Schedule a Call Back

Software

Software

ESI Group offers Software. These are complete software solution for continuous and semi-continuous casting process simulation. They help to decrease the process development time and help to define the optimum process window. The simulation provides an in-depth understanding of the influence of the interacting process conditions allowing a safe and cost effective processing window to be defined; it assesses and optimises the process quality: The chemical composition, phase distribution, grain structure and potential defects such as cracks and pores of the processed material can be predicted. The results of the simulation can be used to increase the overall product quality. Study the sensitivity to material changes and process parameters: slight modifications of the process parameters can have large effects on the product. While in practice it is impossible to test each configuration, simulation allows engineers to quickly check the influence of each parameter. In the same way, process parameters can be adapted for the processing of modified or new alloys. Validate new process design: the design of the new mould, the selection of the casting speed and associated cycle, and the layout of the cooling system can be optimised with preventing expensive engineering changes that could be required later.

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

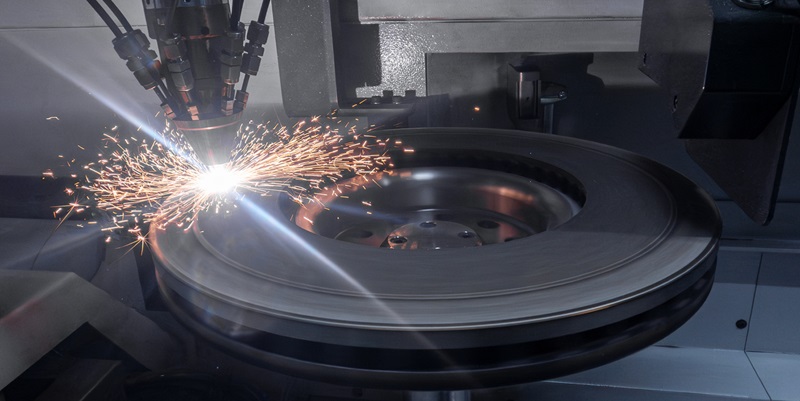

Versatile Machining Capability Through Ram Type Milling & Grinding Heads