Schedule a Call Back

Renishaw 3D Part Verification Software

Renishaw 3D Part Verification Software

Renishaw has consolidated its market leading range of PC-based measurement software for CNC machine tools with a new version of its easy-to-program 3D inspection software, Renishaw OMV. The new version now allows users of multi-axis CNC machine tools to guarantee accurate measurement results through the ability to add two or more alignments in a program. Renishaw OMV 2.02 is also Microsoft® Windows Vista® compatible and offers enhanced graphical reporting with user-configurable tools.

CMM style 3D verification against a CAD model

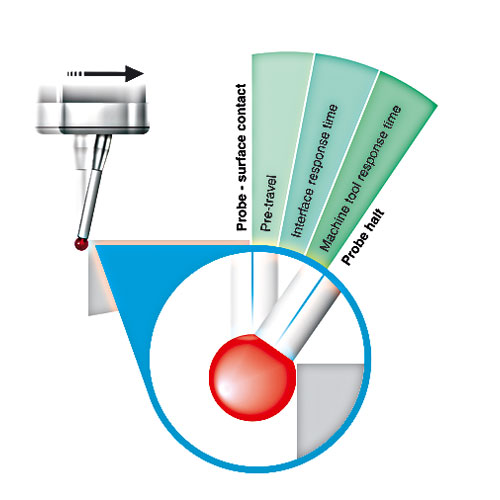

A PC-based part verification package for CNC machine tools, Renishaw OMV gives users powerful co-ordinate measuring machine (CMM) style 3D verification against a CAD model. Operators use an intuitive point-and-click programming interface, and crystal-clear graphical reports of deviations and errors indicate whether a measured point is in, above, or below tolerance, before the part is removed from the machine. Informed decisions can then be made to re-machine a component, or sign off a deviation, long before the part reaches final CMM inspection.

Support for multi-axis machine tools

Renishaw OMV 2.02 is available with an optional multi-axis module that allows part verification programs to operate on a variety of machine tools with 3+2 axis configurations, including tilting/rotating table and heads. A new Orientation Point tool can be used to automatically translate and rotate probe position to the best measurement position, without the need for an operator to manually input the required angle.

Renishaw OMV uses a measured alignment to guarantee accurate measurement results. Version 2.02 also adds the ability to use two or more alignments in a program, which is a significant benefit to users working with components on multi-axis machines or with large or flexible components.

Powerful best-fit algorithms

Renishaw OMV 2.02 features powerful best-fit algorithms, including ‘Max-Material’ and ‘Least-Material’, which match groups of measured data to the CAD model, reducing deviations and errors by removing alignment and datum constraints. When software reports lead to a decision to re-machine a part, these best-fit conditions can also be combined to give instant feedback about any adjustments required to machine tool set-up to ensure a final part within tolerance.

Best-fit operations and the measurement of complex parts are also aided by a data import facility which allows a predefined series of points to be loaded into the software. A series of probe-paths is then automatically generated to measure these data points. This feature has significant benefits for users needing to measure large freeform components, or where specific measurement points are required on a component.

Configurable measurement reports

Graphical and numerical reporting is configurable, allowing feature parameters to be toleranced and displayed. For example, users are presented with at-a-glance views of the distribution of point deviations on printouts, whilst graphical reporting allows measured values to be displayed using colour-coded surface ‘confetti’ points, call-out labels or in-place values. Within version 2.02, labels can now be positioned manually and their orientation is user configurable, whilst the ‘Screen shot’ function has also been improved to allow the size of the resulting image to be configured.

Measurement for a wide range of platforms

Renishaw OMV allows the high-accuracy measurement of features such as multi-point circles, cylinders, cones, spheres and planes. The software supports a range of native CAD files including AutoCAD®, Cimatron®, CATIA®, SDRC, SolidEdge®, SolidWorks®, Unigraphics® and Pro/ENGINEER®, plus standard formats such as IGES, Parasolid, STEP and STL. Machine tool controller compatibility is extensive, including Acramatic, Fanuc, Haas, Heidenhain, Hitachi Seicos, Makino, Mazak ISO, Mori Seiki, Okuma, Selca, Siemens and Yasnac.

An enhanced software package, Renishaw OMV Pro, is also available for more demanding measurement applications, and includes advanced geometric dimensioning and tolerancing (GD&T) functionality. Find out further information about Renishaw’s market-leading range of CNC machine tool probe systems and software.

Products from Renishaw Metrology Systems Limited

Non Contact Vision Measurement Probe

Software For On Machine Measurement

Metal 3D Printing Machine, Dental

Metrology Software Suite, MODUS 2

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads