Schedule a Call Back

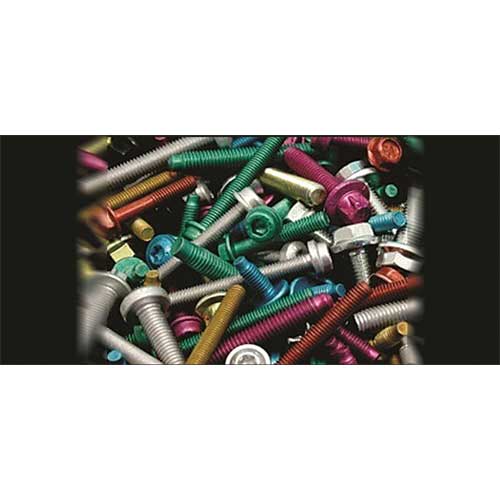

Electro Deposited Coating System

Electro Deposited Coating System

Coatec India designs, manufactures, installs and commissions CED Coating Systems. Electrocoat is the process of depositing an organic coating on a clean metal substrate after phosphate pre treatment. This is an electro chemical reaction. Both anodic and cathodic technologies are used. However, it is the cathodic electro deposited epoxy coating system, which is now prevalent worldwide because of its unmatched corrosion protection.

Electrocoat has many advantages over competing technologies. There are actually no coating technologies for automotive components, which compete with Electrocoat, but nonetheless they do make a valiant attempt. This is a technology being used worldwide over 40 years. It is a very mature system with transfer efficiency in excess of 90%, very low cost of coating material, extremely precise control on coating thickness with very high predictability, very easy to automate and has low labour cost. The parts can be racked densely providing for a very high throughput.

This is considered a benchmark for corrosion protection. The coating is deposited uniformly and the system has a good throwing power for recessed areas. The most important feature about this coating is that the Process is Consistent that handles multi metal structures with equal ease. It is compatible with other topcoat application technologies.

The key benefits of this coating are:

- Extremely high corrosion protection. A 20 micron dry film thickness can withstand as much as 1000 hours salt spray test ASTM B117

- Water-based technology eliminates risk of fire and reduces air and water pollution

- Unlike spray coatings, CED paint does not sag during curing

- Simple Process – eliminates dependence on skilled manpower

- Runs mainly in automated systems

On the environment front, this technology has low to no HAPS and ultra low VOC. The technology is free from heavy metal chemicals. The coating process itself works in a closed loop and therefore the wastewater discharge is minimal. Both OSHA and EPA compliant technologies are available.

Product & Technology News

Products from Coatec India

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads