Schedule a Call Back

Robotic & Automatic Welding Systems

Robotic & Automatic Welding Systems

J N Robotic Automation offers Robotic and Automatic Welding Systems from Dinse GmbH. The company offers precise, reliable, durable automatic assembly solutions in MIG/MAG, TIG, laser, EB, plasma welding and brazing. Dinse can supply robotic and automatic welding equipment for all welding processes in assembly operations. The company offers to consult with clients on location about the advantages of different applications and to show how to obtain the best possible results. In contrast to MIG/MAG welding, TIG, laser, EB and plasma welding all employ a non-arcing feed or filler wire that is fed into the weld puddle and melted into the joint. Robots do not need to work in shifts: 24-hour continuous operation is standard procedure for this welding equipment. The following three factors are of critical importance: highest quality for durable, long service life; highest system availability; and highest reproducibility (repeat accuracy) of all system steps. All system components are fully compatible with each other: sets of welding accessories/fittings, liquid or gas cooled, mounting brackets, safety shut-offs, tool-change stations, testing and adjusting equipment, wire feeders for robotic and automatic applications, and spool housings. Whether liquid or gas cooled, the systems are well-designed and are proven in actual use. Both welding torch cooling systems have high heat-removal capacities. In Dinse dual-circuit liquid cooling, the coolant flows along the full length of the welding torch through numerous longitudinal channels. The contact points and gas nozzle are cooled in parallel. In Dinse gas cooling, the gas cascades through ring-shaped lengthwise channels and extensive lateral ribbing to the gas nozzle. In all Dinse welding torches, the inert shield gas is fed separately, a supply method, which positively prevents gas loss.

- Inert shield gas supply

- Separable welding torch head

- Separable accessories/fittings

- Contact tube clamping for exact centring

- Mounting brackets

- Fixed or mechanically adjustable (longitudinal, lateral, height) in varying extents and angles

- Safety shut off has “run-on†buffering and precise

- Automatic reset

- Can be supplied with ready-to-attach flanges for all robots

Products from J N Robotic Automation Private Limited

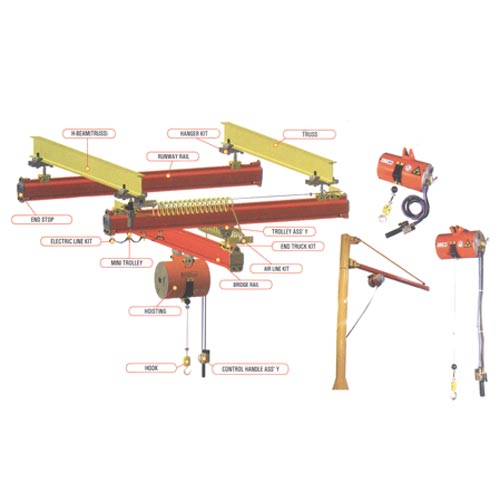

Power Free Rail System & Air Balancers

MMA Welding Machine, Minarc 150/151/220

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads