Schedule a Call Back

Rotary Screw Compressors

Rotary Screw Compressors

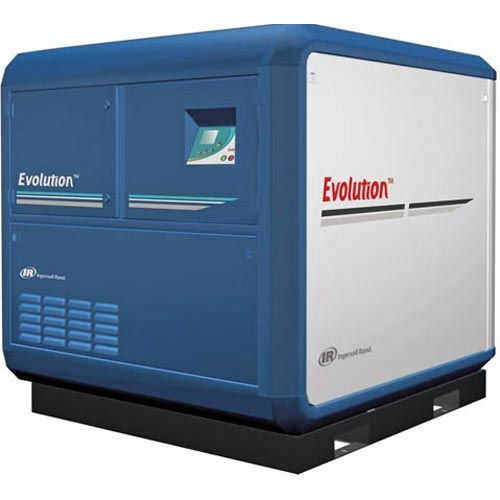

Compressed air, also referred to as the "4th Utility" (after electricity, water & steam) can play a significant role in preparing industries for global competition. It is required at every manufacturing stage in the textile industry. This is also one of those utilities in the sector that consumes maximum energy. Hence it is essential to select an appropriate air compressor while setting up a compressed air system. Ignoring this factor leads to many industries incurring additional maintenance costs and reduced compressor performance such as: - Inadequate compressor control - Air quality (moisture and contamination free) - Traditional approach in maintenance. Ingersoll Rand’s flagship brand EvolutionTM comprises of rotary screw air compressors that are designed to resolve these issues and provide ease of operation, low maintenance and reliable air supply. It has a wide product range including air compressors, air dryers, air receivers and air filters. Customers are served by a wide network of sales and service network across India.

-

More CFM/kW

Air end is treated as the heart of a compressor. Hence it needs to be efficient and generate more volume of air at a low speed. Installed with reliable air end and low speed functioning, EvolutionTM provides more air flow (CFM) with less power consumption (kW). Its German engineered design works towards extended reliability and with less number of leak paths. Low Maintenance Cost The maintenance cost of a product is a critical parameter in decision making today, as it affects the long-term life of a compressor. Unlike competitors, EvolutionTM has designed hour based ready-to-install kits. It helps customers not only to reduce maintenance costs but also increase the life of a compressor. Additionally, it also decreases the downtime against conventional approach of buying and replacing individual parts. - Long life Ultra-coolant

Ultra coolant plays a critical role in efficient functioning of air end. It prevents dry start up and seizures of air end that leads to a longer life. With unique coolant dam in the air end assembly, EvolutionTM, increases productivity and efficiency of air end. It is synthetic in nature and has a long life of 8000 hours. With high thermal conductivity and thermal point, chemical properties are retained even at high temperatures. - Three Stage Separation Systems

In textile operations, Compressed air with minimum oil content is required to ensure high quality fabric. EvolutionTM with its 3 stage Separation system provides clean air with minimum oil content to ensure high quality fabric. - Efficient cooling at 46°C

A cooling system has a major role in preventing discharge of hot air at the outlet. EvolutionTM is designed for the Indian tropical conditions so as to work efficiently at 46°C. It is installed with an optimally designed Aluminum cooler to provide more surface area for cooling and avoid nuisance tripping. - Control at fingertips

A controller helps you to monitor the status of compressor load and operation, continuously. With an advanced microprocessor controller, EvolutionTM provides real time access to following features. - One stop solution – Refrigerant air dryer, air filter and receiver

There is a need for moisture free compressed air to prevent rust and scale formation within pipelines. Moisture may cause equipment failure that increases recurring cost. Integrating with Evolution™ air dryer provides moisture free air to enhance the life of spinning machines. Overall, Ingersoll Rand’s high performance compressor EvolutionTM is well positioned to cater to industry specific needs. This product has been designed to provide ease of operation, low maintenance and reliable air supply to a wide spectrum of customers from varied verticals including automobile, vehicle service stations, colour/rice sorting, sponge iron, plastic and rubber manufacturing and textiles amongst others.

Products from Ingersoll Rand

Cordless Precision Screwdriver QX Series

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads