Schedule a Call Back

Compressed Air Treatment Using Catalyst Technology

Compressed Air Treatment Using Catalyst Technology

BEKO Compressed Air Technologies offers Bekokat devices for oil free air from lubricated compressors. The new catalyst system provides a constant supply of oil-free compressed air with a barely detectable max residual oil content of 0.003 milligram per cubic metre. With this high level of efficiency, the Bekokat devices can sail past the stringent oil content stipulations of DIN EN8573- 1/ISO 8573-1, class 1. At the same time, the new catalytic principle breaks down the technical and economic barriers that are usually intrinsic to conventional compressed air treatment, especially when concerned with applications with extremely high quality requirements. The catalyst comprises a granulate that is heated to an operating temperature of around 150°C. In the catalyst, the oil molecules are broken up until only a carbon atom remains. At the end of the final catalytic phase, the oil molecules have oxidised to H2O and CO2. The oil-free and dry compressed air can then be used for the given application; the remaining water is discharged via a standard method. Consequently, Bekokat systems are not only highly effective, but also very environmentally friendly. Bekokat’s advantages further include a maximum of process reliability because catalytic oxidation takes place completely independent of ambient temperature, inlet temperature, air humidity, and oil inlet concentration. Even during partial load operation, the efficiency of the catalyst technology of the Bekokat device is not in any way reduced. In economic terms, the exceptionally long useful life of the special Bekokat granulate – around 20,000 hours – is somewhat of an evolutionary leap considering that conventional activated carbon fills need to be replaced after about 300 hours of operation.

Product & Technology News

Products from BEKO Compressed Air Technologies Private Limited

Catalyst for Compressed Air Treatment

Compressed Air Dryer, Drypoint RA

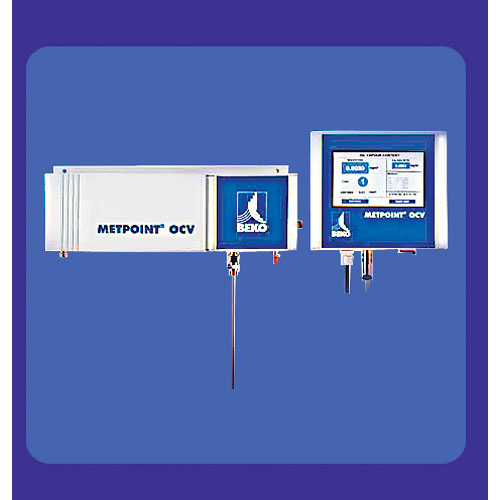

Oil Monitor For Compressed Air, Metpoint OCV

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads