Schedule a Call Back

Curved Tooth Flexible Gear Coupling

Curved Tooth Flexible Gear Coupling

Reva curved tooth flexible gear couplings are manufactured as per IPPS: 1-01-005-86. The design aims at achieving rationalisation of sizes and numbers on basis of their torque transmitting capacity and generally synchronises Reva's modular gearbox ratings, which in turn are rated in increasing geometrical progression. Gear hubs and outer sleaves are manufactured from cast steel conforming to IS:1030 for first three sizes and IS:1570 for remaining sizes. Teeth are generated by involute system having 30 degree pressure angle instead of 20 degree to make a quantum breakthrough in flange coupling design and performance. Crowned-backlash-free hubs are selected for highest torque transmission, greater flexibility and ease of alignment. The teeth are induction hardened to 42 HRC. Sleeves: internal teeth cut by gear shaping method are induction hardened to 45 HRC. High tensile (8.8 quality) bolts are used in joining two halves with a gasket in between them. Lubrication: for ambient temperatures below 65.5°C, mineral oil with viscosity>150 SSU (32.1 CS)<1000 SSU (220 CS) at 99° can be used. Calcium based EP type grease consistency No.2 or graphite grease of consistency No.2 as per IS:508-1984 with graphite content 10-20% shall be used.

Products from Reva Industries Limited

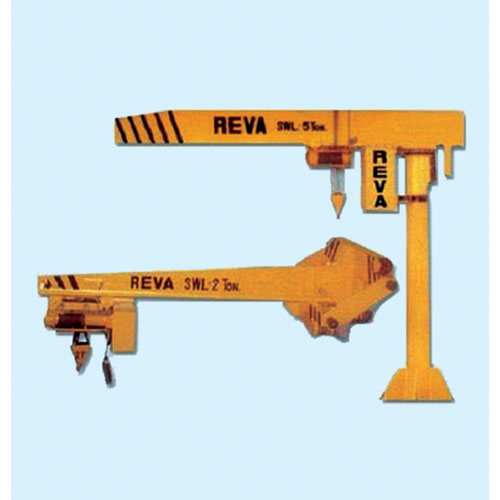

Electric Overhead Traveling Cranes

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

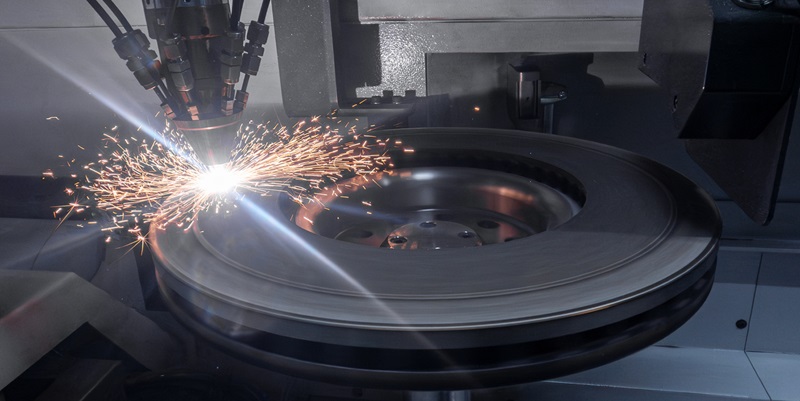

Versatile Machining Capability Through Ram Type Milling & Grinding Heads