Schedule a Call Back

Mould Base

Mould Base

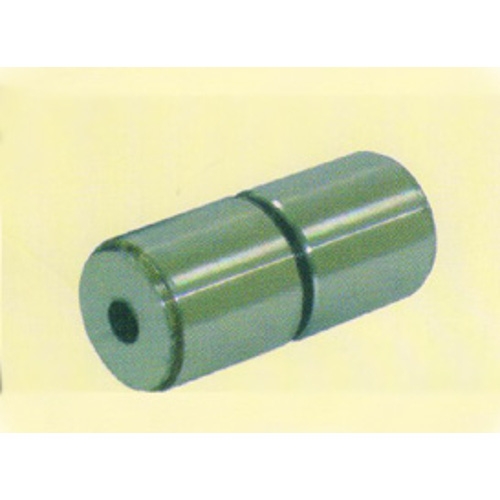

Ashna Enterprise offers various Mould Base such as Standard Mould Base, Customised Mould Base, Injection Mould Base, Pressure Die Casting Mould Base and Compression Mould Base.

Standard Mould Base

Standard Mould Base is generally used in prototype moulding and short-runs. These moulds offer the flexibility to perform more value-added work, with significant reduction in the mould base cost. The production process is concentrated on providing high quality mould bases for plastic. The company also provide different range of mould base for die casting dies as per the application and specifications of the clients.

Customised Mould Base

Customised Mould Base is generally used in prototype moulding and short-runs which is used for various industrial purposes. This mould base provides excellent performance, close tolerance, customised parts and various material choices. The company manufacture customised mould base as per customer drawing with cooling line.

Injection Mould Base

Injection Mould Base is used for assisting plastic and moulding such as household mould, communication mould and kinds of mould. Injection moulding is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, glasses, elastomer, confections, and most commonly thermoplastic and thermosetting polymers. Parts to be injection moulded must be very carefully designed to facilitate the moulding process.

Pressure Die Casting Mould Base

Pressure Die Casting Mould Base is highly demanded in the market due to their high quality and unsurpassed performance. Every step of fabrication of pressure die casting mould base is controlled by skilled professionals to maintain the high level of quality. Designed as per the specifications of clients, these pressure die casting mould base are precisely maintained through micro finishing operation with EDM parameters.

Compression Mould Base

Compression moulding is a method of moulding in which the plastic, generally preheated, is first placed in an open, heated mould cavity. There are four step in compression moulds: loaded charge, charge compressed, cured the charge and ejecting process of product. The main construction is punch (cavity side), core moulds and ejection system.

Product & Technology News

Products from Ashna Enterprise

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads