Schedule a Call Back

Pneumatic Level Switches

Pneumatic Level Switches

Pneumatic Level Switches are used in application where electrical switching is not recommended or electricity is not available. These systems require minimum 2 kg/cm2 clean filtered air, preferably through an AFR. In Order to protect the switch assembly from contaminants, filtered and dried gas/air supply is recommended.

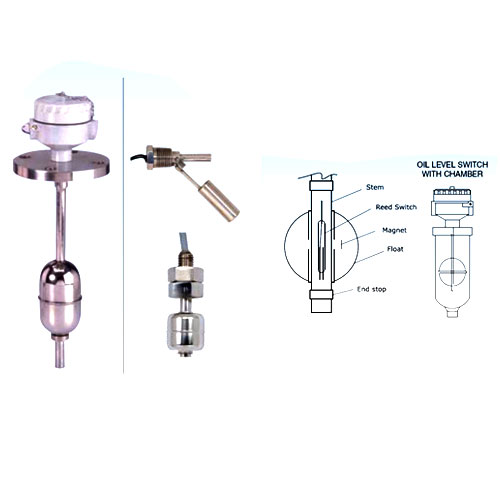

Side Mounted(with / without cage):Buoyancy force of process liquid on a float causes the float to move with the liquid's surface. Float movement pivots a magnet into the field of a like-charged switch magnet. As the magnets repel each other, the switch magnet moves, actuating the switch.Free swinging float arm - No cavities to clog (eliminates “Float Stickâ€), Magnetically activated - No seals to maintain / No leaks / No fugitive emissions.

Top Mounted Float/ Displacer(with/without cage):

Operation is based upon simple buoyancy, whereby a float or a spring loaded weighted displacer rises following the liquid level. A magnetic sleeve, connected to the float / displacer, moves up and operates within a non-magnetic enclosure tube. The magnetic sleeve attracts a pivoted magnet, actuating a switch mechanism located

out-side the enclosure tube to give NO or NC changeover. A fall of liquid level will de-actuate the switch mechanism

Product & Technology News

- Scrubbers and Separators

- H2S & CO2 Service

- Process Vessels

- Water / Fuel Tanks

- Bulk Liquid Storage

- Radiator Level

- Oil Sumps

- Day Tanks

- Operating Pressure : 2 - 8 Bar

- Permissible Fluids : Air/Inert Gas

- Fluid Temperature : -10 to +50 Deg C

- Connection Size : 1/8†NPT / ¼†NPT

- Switch Differential : Within 20 mm (float type)

- Process Pressure : Up to 20 Bar / Specified

- Process Temperature : -10 to 75 Deg C / Specified

Products from Sigma Instruments Company

Magnetic Float Operated Level Transmitter

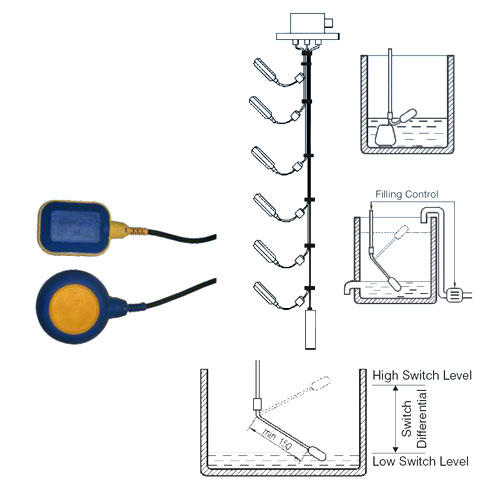

Cable Float (Tilt Type) Switch

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads