Schedule a Call Back

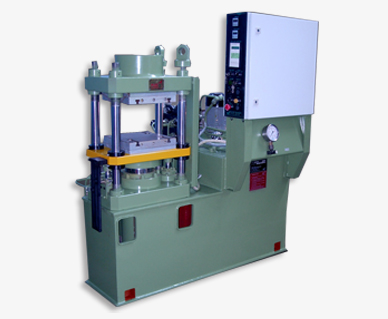

Vacuum moulding machine for precision rubber components

Vacuum moulding machine for precision rubber components

Plus-One MachineFabrik offers a vacuum moulding machine for precision rubber components. This is hydraulically operated automatic vacuum moulding machine used for manufacturing precision moulded rubber components where reliable, repeated quality is must like valve part, seals, etc. One can use multicavity moulds with maximum three plates-design in this machine. This machine consists of two sections, one part is vacuum moulding press and second one is automatic mould ejection system and both these segments are connected with automatic mould handling arrangement, sequenced with press operation. The moulding section is closed frame type compression moulding press with sliding door which is vacuumised during compression moulding operation, vacuum system with its unique design creates vacuum in press chamber instantly. Vacuum system, hydraulic systems and temperature control systems all are regulated through programmable logic controls. Complete moulding process is automatic and as the moulding is done in the vacuum, components are moulded without any porosity and with assured control of parameters. The machine is compact and designed for minimum maintenance and ease of operation. Temperature of the platens is critically controlled with PID type temperature controllers. The machine heating is started automatically before starting the working shift, so that pre-heating time is saved.

Product & Technology News

Products from Plus-One Machinefabrik

Compression Rubber Moulding Machines

Vacuum Compression/Transfer Moulding Machines

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads