Schedule a Call Back

Wire-Feed Systems for Robotic & Automatic Welding

Wire-Feed Systems for Robotic & Automatic Welding

J N Robotic Automation offers Wire-Feed Systems for Robotic and Automatic Welding from Dinse GmbH. These are push-push and push-pull wire-feed technologies. Push-Push operation: here, the torque-controlled motor advances the feed wire. The maximum torque, or feeding force, is adjustable to prevent the feed wire from bowing or kinking. The speed-controlled motor in the welding torch head takes up the exact amount of feed wire required. The wire feed is constant and unaffected by torsion, bending and the length of the accessory/fitting in use, which is particularly critical when feeding thin and soft wires over long distances. Push-Pull operation: here, the drives in the wire feeder and the welding torch head are linked so that the feed wire in the whole set-up remains under constant tension. This method ensures a constant feed rate over long distances when feeding wires with large cross-sections such as flat wire. Features: the flexible, variable system with sets of accessories/fittings, wire feeders and spool housings, high performance, proven systems for welding and brazing, reliable wiring feeding through feed modules in light-weight, fully insulated plastic housings, compatible with different spool sizes, accepts all commonly available power sources. Wire feed methods: continuous for push-pull and push-pull.

Products from J N Robotic Automation Private Limited

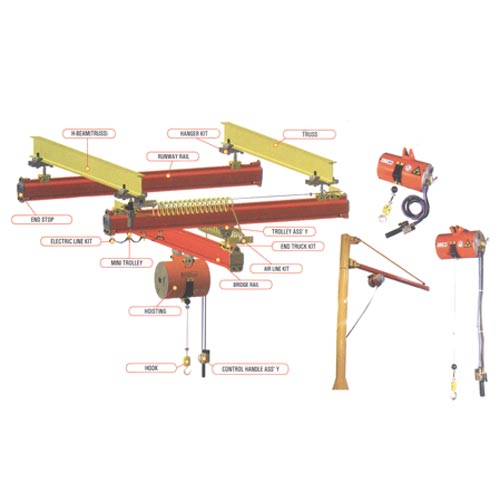

Power Free Rail System & Air Balancers

MMA Welding Machine, Minarc 150/151/220

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads