Schedule a Call Back

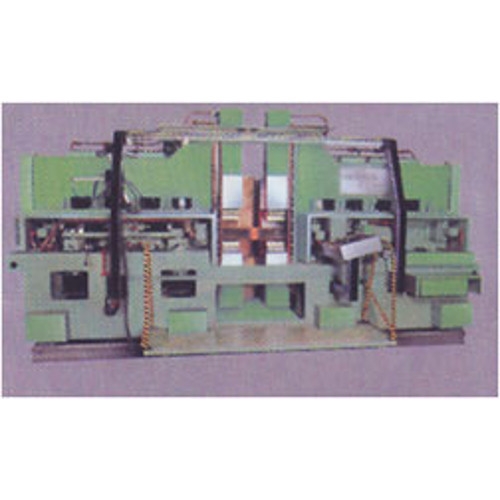

Seam Welding Machine

Seam Welding Machine

Seam Welding Machine is precision built, with careful design and robust construction, suitable for long trouble free service. Each machine is submitted to rigorous proving tests before delivery is made, in order that the machine may be ready for immediate installation and operations at customer's works.

The Know-How that enables MECHALONIC ENGINEERS to offer these machines is backed by many years of experience in Welding Technology.

Machines covered under this section are single phase AC for seam welding application in the manufacture of Drums & Barrels, Fuel Tank, silencer, Muffler, Shock Absorber, etc.

SPMs AND THREE PHASE D.C. MACHINES:

Mechelonic Engineers have in their range a number of SPMs for seam welding applications for jobs, such as fully automatic barrel and shell welding (longitudinal), tub cover welding (circumferential), shock absorber welding, fuel

tank welding and other automobile components. Mechelonic Engineers also have seam-welding machine with 3-phase DC transformer and matching controls.

Specifications:

Ratings KVA:

50, 75, 100 150, 200.

Construction:

Robust construction, streamlined appearance with maximum resistance to deflection. Welding transformer enclosed in the main frame, pneumatic control mounted on the machine.

Welding Transformer:

Transformer conforms to IS: 4804 Part-I and RWMA Standards, water-cooled, class 'F' insulation with thermo switch protection for overloading.

Current Control:

Welding current adjustable from 50 to 100% by means of a tap change links.

Cooling System:

Thyristors, Transformer, Secondary connections and electrode wheels are water-cooled.

Electrode Force:

Upper arm is actuated by heavy-duty 2-way pneumatic cylinder, controlled by solenoid valve. Compressed air at 2.0 Kg/cm.sq. to 5.6 kg/cm.sq. provides electrode force.

Air filter, lubricator, regulator, pressure gauge are provided as standard accessories.

Electrode Drive:

Machines are provided with different drive system depending on the application. Customer to specify the preferred system.

Direct Drive: Direct Gear is given to any one of the wheels

Knurl Drive: One of the Wheels or both are driven through a serrated hardened wheel depending on the style of welding. Constant dressing of weld wheel of maintains uniform profile, constant welding speed irrespective of weld

wheel diameter are some of the advantages of knurl drive system.

Narrow Track Seam Welding (Optional at Additional Cost):

In order to weld coated sheets for application like fuel tank, machine with narrow track welding (2.5 to 3 mm weld width) facility could also be supplied. In narrow track seam welding, weld wheels are of thickness 6 mm constantly

coined for circular profile, which results in narrow contact with very high-pressure density. Due to this high-pressure density the coated material on the sheet metal is squeezed out during the welding.

Motor Drive:

Machine will be supplied with drive system comprising AC squirrel cage induction motor, with variable speed AC drive and Reduction GearBox as standard.

| Model>> Longitudinal | SL-50 to SL-200 |

| Model>>Circumferential | SL-50 to SC-200 |

| Rating KVA @ 50% duty cycle | 50 to 200 |

| Upper electrode cylinder stroke max. (mm) | 50 |

| Vertical adjustability of ram (mm) | 50 |

| Max available +/- 10% @ 460 throat depth0 (KAmps) | Up to 30 |

| Max. electrode forve @5.62 kg/cm sq. (Kgf) | 440 up to 990 |

Products from Mechelonic Engineers Private Limited

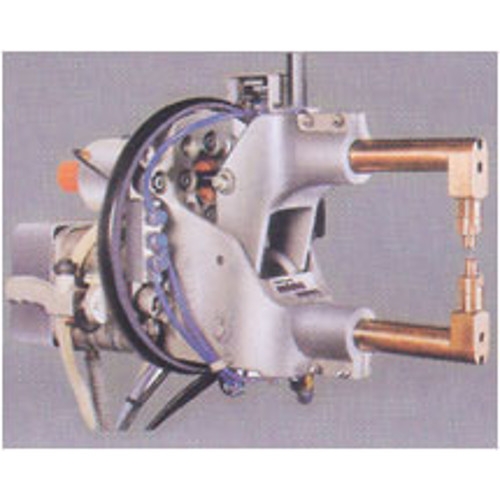

Portable And Integral Type Spot Welder

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads