Schedule a Call Back

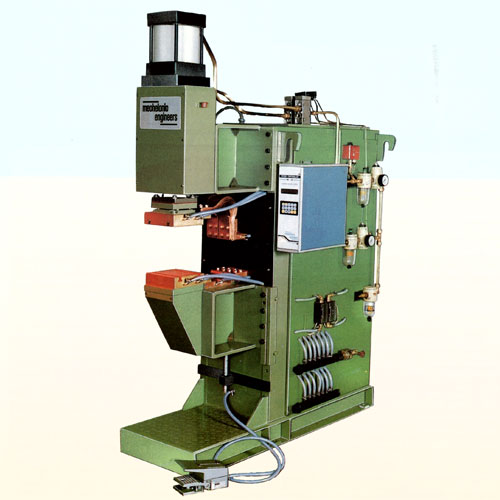

Press Type Projection Welders

Press Type Projection Welders

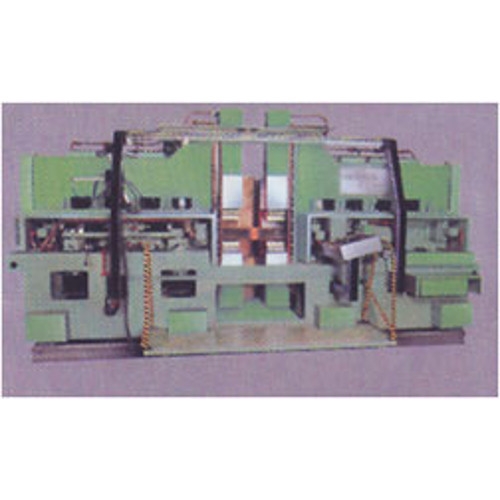

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting.

Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic

operation.

These machines are designed and manufactured conforming to the Indian Standard Specification No.IS:4804 Part I and III by a team of highly experienced engineers in welding technology.

Specifications:

Standard Ratings:

50, 75, 100, 150, 250 and 300 KVA @ 50% duty cycle.

Type:

Air operated, stationary press type projection welding machine with pneumatic cylinder mounted directly on the upper arm.

Construction:

Main frame of the machine is of heavy, rigidly reinforced welded steel construction, streamlined appearance with maximum resistance to deflection. Transformer enclosed in the main frame and pneumatic accessories mounted on

the side of the machine and upper and lower arms mounted directly on the frame. Current is carried from the upper transformer terminal to the upper platen tooling through a 'U' shaped laminated copper flexible link designed to

provide rolling action as the welding head reciprocates during operation. The welding head is of antifriction type. The pneumatic controls mounted on the side of the machine. The operating control station mounted on the machine

is clearly visible and within easy reach of the operator.

Standard Throat Depths:

300, 450, 750 mm.

Welding Transformer:

Transformer conforms to IS:4804 Part-I and RWMA Standards, water cooled, class 'F' insulation with thermo switch protection for overloading.

Current Control:

Welding current adjustable from 50 to 100% by means of a tap change links.

Cooling System:

Transformer, Bus Bars, Platens, Electrode and Thyristors are water cooled, followed by discharge to an open drain-pot for visual observation of flow.

Water Flow Switch (Optional at Extra Cost):

Water flow switches may be provided with the machine to ensure adequate flow of the water for Transformer and Thyristor circuits while operating the machine.

Platens:

Constructed from high quality copper alloy accurately machined, having 'T' slots to international standards.

Dies Toolings:

Machine can be provided with custom-designed projection welding dies to suit various sizes and shapes of work pieces, and suitable jigs and fixtures for holding, guiding and indexing of the work pieces, as required, at extra cost.

Electrode Control System:

Upper electrode actuated by a heavy duty 2-way cushioned pneumatic cylinder controlled by an electrically operated solenoid valve. Compressed air at 1.5 Kg/cm2 - 7.0 kg/cm2 (20 to 100 p.s.i.) acting on the pneumatic cylinder

provides electrode force. Machine provided with air filter, air lubricator, air pressure regulating valve and air pressure gauge.

High Lift Facility (Optional at Extra Cost):

"High Lift" (retractable upper electrode) facility shall be provided by means of special cylinder. A hard/foot operated air valve causes the upper electrode to lift to the top most position for easy introduction of the job into the throat of

the machine. The retraction as well as the working stroke is adjustable within a range.

Dual Pressure System (Optional at Extra Cost):

Dual pressure system shall be provided by means of 2 sets of regulating and controlling devices and the necessary air circuits. Working in conjunction with special control units, this facility would enable application of a higher force

on the job being welded at any point during the weld cycle.

Air Reservoir (Optional at Extra Cost):

An air reservoir of suitable capacity shall be provided to minimise pressure drop during welding.

Adjustment of Welding (Electrode) Force:

By adjusting the air pressure regulator provided on the machine.

Adjustment of Throat Gap:

By vertical adjustment of lower arm.

Weld Initiation:

By means of operator's foot switch / hand operated switch connected to a low voltage safe initiating circuit.

Controls:

Appropriate Control will be incorporated with the machine as per requirement.

Service Requirements

Power Supply:

415 V, single phase, 50 cycles, Machine suitable for connection to 2 lines of 3 phase supply. Main supply cables 2-core type, disconnect switch with fuses of size recommended to be provided by the customer.

Compressed Air:

Customer to provide air supply at recommended flow volume at a minimum pressure of 5.6 kg/cm2 (80 p.s.i.).

Cooling Water:

Cooling water at minimum 2.1 kg/cm2 pressure and temperature below 30oC at recommended flow rate to be provided by the customer.

Product & Technology News

| Model | Â | SP-50 | SP-75 | SP-100 | SP-150 | SP-250 | SP-300 | |

| Rating @ 50% duty cycle | KVA | 50 | 75 | 100 | 150 | 250 | 300 | |

| Max. Short circuit | 300 mm | Amps | 30000 | 40000 | 50000 | 65000 | 86000 | Â |

| Secondary Current (+/- 10%) | 450 mm | Amps | 26000 | 33000 | 40000 | 53000 | 70000 | 80000 |

| at throat depth | 750 mm | Amps | 23000 | 30000 | 38000 | 50000 | 66000 | 74000 |

| Max. Demand KVA @5% duty cycle | KVA | 160 | 240 | 315 | 475 | 800 | 950 | |

| Primary current @Max. | Â | Â | Â | Â | Â | Â | Â | |

| Demand KVA & 415 Volts | Amps | 385 | 578 | 760 | 1140 | 1930 | 2300 | |

| Electrode stroke | mm | 75 | 75 | 75 | 75 | 100 | 100 | |

Products from Mechelonic Engineers Private Limited

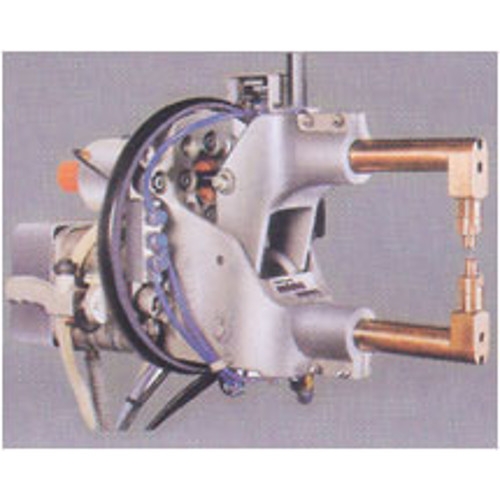

Portable And Integral Type Spot Welder

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads