Schedule a Call Back

Dip Spin Machine for Coating

Dip Spin Machine for Coating

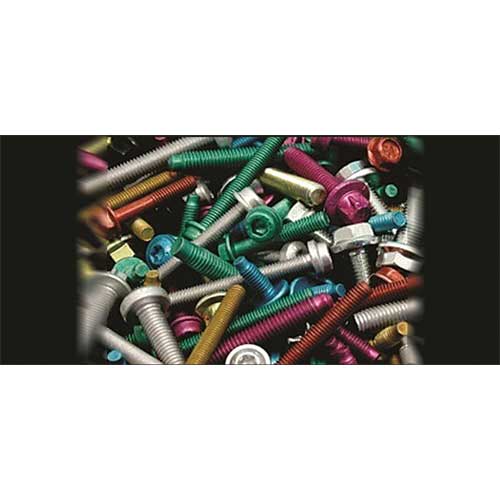

Coatec India, established in 1992, under the banner ‘Making Technology Affordable™’, supplies Dip Spin Machine for Zinc Flake coating of bulk parts like fasteners. This process is not directly suitable for coating of sheet metal parts with flat surfaces. Such components with flat surfaces can be coated with a modified dip spin method or best by simple spray and bake method. Dip spin coating machine is used to give a surface coating which raises the corrosion resistance (salt spray test from 120 hours to 1000 hours) and is useful for coating fasteners, clamps, U bolts, nails, screws, etc., that need high corrosion resistance. Process involves placing the phosphate pre-treated products in a mesh basket submerged in coating solutions and spun to remove the excess coating. The machine can also be run in the manual mode. All controls and alarms are through the touch screen. The machine can handle 10 kg of fasteners per batch. The maximum RPM is 400. The time for each batch will depend upon the process sequence and the timings selected. Normally a cycle time of 5 minutes is considered taking loading and unloading into account. The machine comes with two baskets. The machine is available in three models: Dip Spin, Dip Spin Tilt and Dip Spin Tilt with chiller. Dip spin coating minimises cost of both material and waste disposal.

Product & Technology News

Products from Coatec India

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads