Schedule a Call Back

Surface Treatment

Surface Treatment

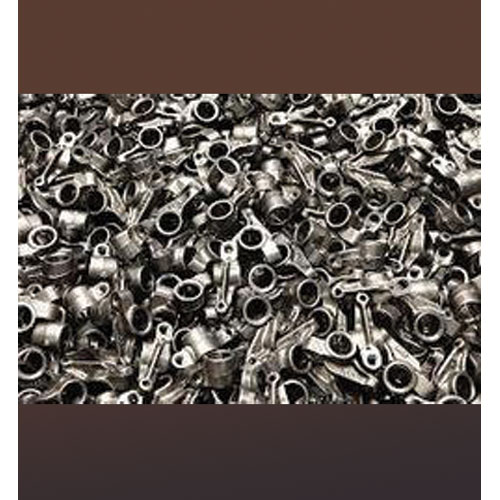

Modern surface-coating techniques to make sure that products look aesthetically good and last long in sheet steel fabricated assemblies.

- There are various method of surface coating like power coating, epoxy painting, zinc plating; a sheet steel assembly surface needs to be prepared for coating as there are several infirmities and impurities that can act as a hindrance for protective coating

- In order to ensure a good bonding between the metal and the protective coat, various methods like shot blasting and liquid dipping are used, depending on the type of material

- Sandblasting is, propelling very fine bits of sand at high-velocity to clean or etch a surface; sand blasting process helps remove oil and rust layers on the surface of the product, which ensures quality in surface coating; seven tank cleaning is a chemical process,

- Oils and greases are removed in weak alkali or neutral detergent solutions and the surface is etched to remove heavy oxides.

IPF Surface Treatment Solutions

Surface Treatment Solutions

Surface

Treatment

Solutions

Surface Treatment

Treatment Solutions

Rishi Laser Limited

Rishi

Laser

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Verified

Verified

Versatile Machining Capability Through Ram Type Milling & Grinding Heads

Deburring, Drilling, Boring, Tapping and Threading Machines

Verified

Verified

Polygon Turning Machine - TPT-5S, TPT-5ST

Deburring, Drilling, Boring, Tapping and Threading Machines