Schedule a Call Back

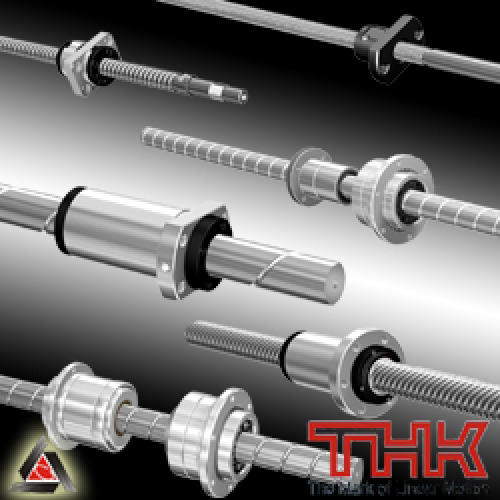

THK Ball Screws & Ball Splines

THK Ball Screws & Ball Splines

'Ball screws' have replaced the Sliding screw or Lead screw mainly because the driving torque required is One Third of what is required by the conventional lead screw. Ball screws have balls in the nut that roll between the screw shaft and the nut to achieve high efficiency in driving torque. So they can be used not only for converting Rotational motion to Linear motion but also for converting Linear to Rotary motion. Since ball screws require a minimum starting torque, they can be used for micro feeding. Fast feeding is possible since they generate minimum heat and are highly efficient.

Caged Ball Technology

THK has developed a new technology for Ball screws called the Caged Ball Technology where the balls don’t touch each other but are separated by a cage structure which keeps the balls aligned. Caged Ball Technology provides:

- Quiet Operation - Interference noise between balls is eliminated

- Orderly Ball Movement - Balls are held by the cage in the form of a belt. They are aligned uniformly and move in a circulating manner. There is no skewing of the balls, any sudden variations in friction are also eliminated.

- Excellent High-Speed Performance - Eliminates heat generation due to uniform friction between balls

- Long Service Life - Grease pockets are provided consecutively over the entire ball circulating path to constantly lubricate the balls enabling long-term, maintenance-free operation and Long Service Life.

Types of Ball Screws

Ball screws are mainly classified into 2 types viz. Precision and Rolled Ball screws

1. Precision Caged Ball Screw

|

|

|

2. Precision Ball Screw

|

|

|

3. Precision Rotary Ball Screw

|

|

|

4. Precision Ball Screw/Spline

|

|

|

5. Rolled Ball Screw

|

|

Ball Screw Peripherals

THK provides Standardized Support Units for Ball screw assembly. BK and BF models are general purpose supports while EF, FK, EK, FF models are for finished shaft ends. Supports differ in shape (square or round) and whether they are used on the fixed end or supporting end. Nut Bracket MC for direct mounting and Lock nut RN for accurate fastening, are also available.

QZ lubricator module can be attached to feed the right amount of oil to the raceway. It extends the lubrication maintenance period considerably and prevents contamination of surrounding and oil wastage caused due to forced lubrication. For E.g. QZ lubricator was tested and compared to forced lubrication and 32 cm3 THK AFA grease used through QZ provided the same lubrication as 15000 cm3 of grease through forced lubrication.

Wiper ring (W) can also be attached to prevent foreign particles from entering the ball screw. It also reduces the flowing out of grease and is highly wear resistant for long term usage.

Ball Splines

The Ball Spline is an innovative LM system in which the balls placed in the spline nut transmit torque while moving on precision ground raceways of the shaft. As the nut can provide preload, THK Ball spline performs well in environment subject to vibrations and impact loads or where high speed kinetics are required. THK Ball Spline can bear 10 times the load as compared to LM Bush and Shaft configuration of same shaft dia. So system can be made more compact using Ball Spline. Unlike LM Bush, Ball spline will not have any rolling action and this gives better performance.

Types of Ball Splines

- High Torque Ball Splines: Shaft has 3 crests formed at 120°. Six rows of balls are arranged to hold the crest. Angular contact design allows even preloading. The different types available are LBS (Cylindrical, Medium load), LBST (Heavy load), LBF (Flanged type), LBR (Flanged, Heavy Load) and LBH (Rectangular). They are used in arms of industrial robots, automatic loaders, conveyance systems, speed gears, precision indexing shafts, etc.

- Medium Torque Ball Splines: Shaft has either 2 or 3 crests with 4 or 6 rows of balls holding the crests for giving the necessary preload. Circular grooves give these models edge in having large loads in radial and torque direction. The different types made are LT (Cylindrical) and LF (Flanged). Various Spline shafts are also provided for specific use for E.g. N type Hollow spline shaft for piping or weight reduction. They are used in industrial robots, spot welding machines, XY recorders, etc.

- Rotary Ball splines: These are either based on LBR model but with either gear teeth on the flange circumference and radial and thrust bearings on the nut (LBG, LBGT used in Speed Gears for high torque transmission) or with Support Bearing directly integrated (LTR, LTR-A used in wire winders, Z axis of robots).

Product & Technology News

Products from Amcats Private Limited

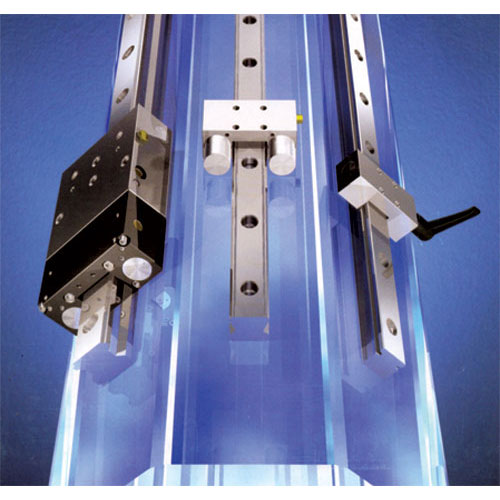

Clamping & Braking Elements For Linear Guides

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads