Schedule a Call Back

Low Friction Cylinders for Counterbalance: A Rational Solution for Machine Tools

Low Friction Cylinders for Counterbalance: A Rational Solution for Machine Tools

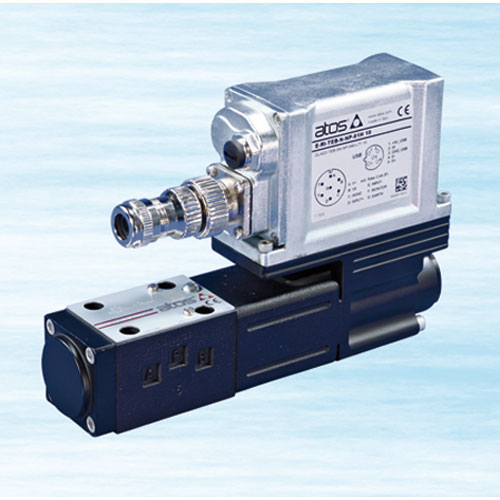

Machining centres and universal milling-boring machines are featured by vertical axis tool driving units performing upward and downward movements of the spindle head driven by electric motor. These machines are usually equipped with accurate hydraulic counterbalance systems, supporting the weight of the saddle and spindle mass. The best hydraulic counterbalance solution, in terms of motion performances, machine integration and easy maintenance, is realised by a small vane pump charging a bladder accumulator connected to a low friction cylinder that counterweights the spindle head load. A proportional pressure-reducing valve modulates the counter pressure value according to the load and working stroke variations. The cylinder plays a basic role for the best machining accuracy and precision by performing low friction sealing during the slow machining motions and by granting zero leaking to avoid the accumulators’ oil discharge.

Products from Atos S p a, Indian Liaison Office

Hydraulic Pumps, Atex Certified

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads