Schedule a Call Back

Komet Group: Over 1000 new tools for successful machining

Komet Group: Over 1000 new tools for successful machining

At the EMO 2015, the Komet Group is showcasing a wide

range of innovations under the slogan “The Cutting

Edge – Solutions for the best performanceâ€. The highlight

will be the extended range of indexable insert milling cutters,

accompanied by many new diamond indexable inserts and

new tools from the fields of drilling, reaming and threading.

Over 1000 additional precision tools have been added to the

Komet® product range.

In addition to its well-known innovative tools for highprecision

drilling, reaming and threading, the Komet Group

now boasts a wide range of high-performance milling cutters.

Some examples: The new Komet milling cutters include

the Komet Q55-KCM (Komet copy-milling) copy miller that

is particularly suitable for machining turbine blades, but can

also be used very universally.

The 45° Komet

Q63-KFM (Komet facemilling)

face milling cutter

is also part of the

new product range. It is

designed for face-milling

operations with a cutting

depth of up to 6.5 mm

and a tooth feed of up

to 0.5 mm. The Komet

Q56-KHF (Komet highfeed)

face-milling cutter

is a particularly efficient

tool. It was designed for

high-feed applications

and achieves a very high

chip volume per unit of time. Its angled cutting edge also

achieves optimum surface quality. The Komet Q43-KSM

(Komet shoulder-milling) shoulder milling cutter produces

shoulders that are step-free and are exactly 90° as a result of

its soft-cutting geometry.

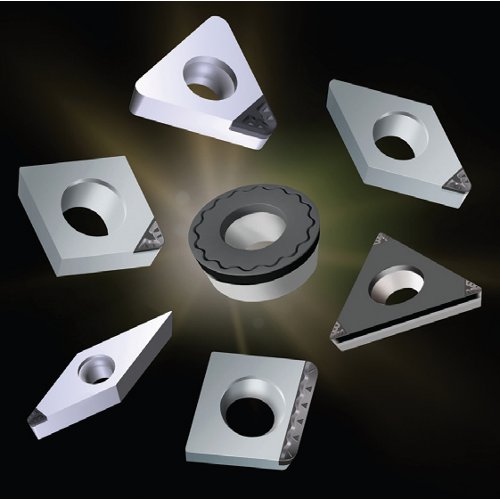

With over 70 indexable inserts featuring different topographies,

substrates and coatings, which can be combined with 60

different basic body designs, Komet now has a full and varied

product range, ideal for handling all milling tasks, from face,

shoulder and chamfer milling to straight, 45° and T-slot milling,

circular and plunge milling, angled plunge milling and

free-form milling.

The range of ISO

indexable inserts with

diamond cutting edges

has also experienced

huge growth and has

been extended to more

than 900 items. In addition

to Komet PCD

products, CVD thick film

diamond-tipped inserts

can now also be supplied.

All variants are manufactured

using the latest

production technology,

such as laser machining

and high-vacuum soldering,

which results in high-quality cutting edges and

variable geometries as well as

improved cutting results and

longer tool life.

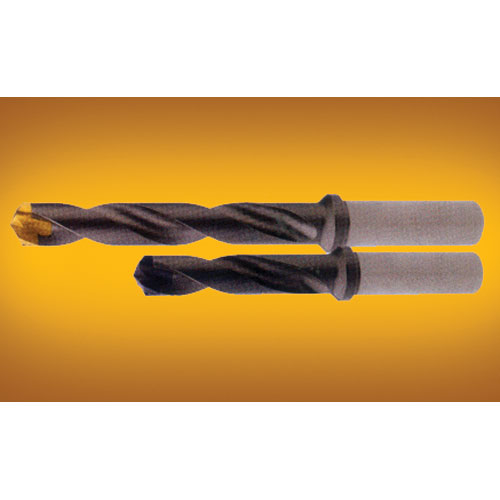

HSS taps with carbide

strips were only available as

special tools until now. The

Komet JEL® GG HML tools

are now available ex stock

and in the sizes M6 to M12

as standard in the catalogue.

These taps combine the benefits

of a flexible HSS shank

with the advantages of a hard

carbide cutting edge. They

can thus compensate for slight

alignment faults and, at the

same time, achieve long tool

life. The Komet JEL GG HML

taps are achieving particularly

good results in machining grey

cast iron (GG) and vermicular

cast iron (GJV).

In addition to its new tools,

the Komet Group, a singlesource

supplier of precision

tools, also offers numerous

additional services, for example through its service brand

Komet® Brinkhaus. The subsidiary develops, produces and

markets monitoring and control systems for machine tools.

An important addition to the customer-oriented range of

tools is provided by the second service brand: Komet Service

®. A network of highly-qualified Komet Service partners,

linked together in a franchise system, provides a professional

regrinding service, reliably and at short notice, and is also

responsible for the sale of solid carbide, carbide-tipped and

HSS standard tools from the Komet Group.

Product & Technology News

Products from Komet Precision Tools India Private Limited

Core Bit Drill with Two New Centring Points

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads