Schedule a Call Back

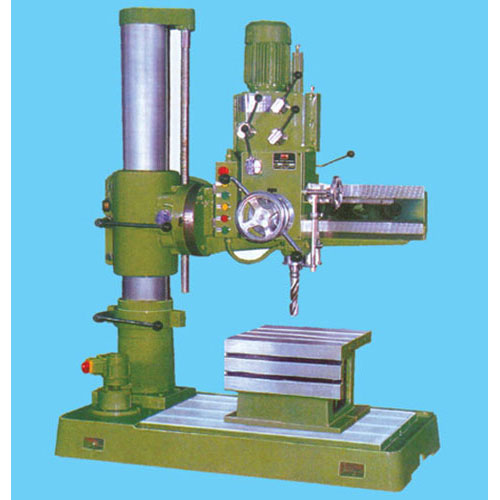

Radial Drilling Machine

Radial Drilling Machine

Poly Kraft Machines offers an all geared Radial Drilling Machine, Model RD-40/1000.

- Base made of one-piece casting, rigidly cross ribbed and an integrated reservoir for coolant

- The “Tee†slots on the surface are machined and the surface hand scraped

- The column is of high Brinell hardness number, and as there are no rotating joints there in, it is quite rigid

- Automatic vertical movement of the arm is provided with direct coupled flange motor on the bracket

- The lead screw will not rotate even while automatic movement will be in operation

- The arm is adjustable to any angular position

- The drill head is mounted on the electric motor is directly mounted on drill head

- Eight different speeds from 90 to 860 RPM are obtained by changing levers

- Automatic feed mechanism is provided for vertical traverse of quill

- The toughened spindle is made of high grade alloy steel is carried in preloaded taper roller bearings to absorb reverse trust and radial loads produced by drilling and boring

- The spindle rotates and slides in ball bearings

- The machine is supplied with two electric motors; and

- Electricals are suitable for 440 V, 50 Hz, 3-phase AC supply

Radial Drilling Machine

RD-40 1000 Radial Drilling Machine

Drilling Machine

Industrial Drilling Machine

Products from Poly Kraft Machines

Verified

Pillar Drilling Machine, Model AP-40

Deburring, Drilling, Boring, Tapping and Threading Machines

Verified

Verified

Horizontal Boring & Facing Machine

Deburring, Drilling, Boring, Tapping and Threading Machines

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Verified

Verified

Versatile Machining Capability Through Ram Type Milling & Grinding Heads

Deburring, Drilling, Boring, Tapping and Threading Machines

Verified

Verified