Schedule a Call Back

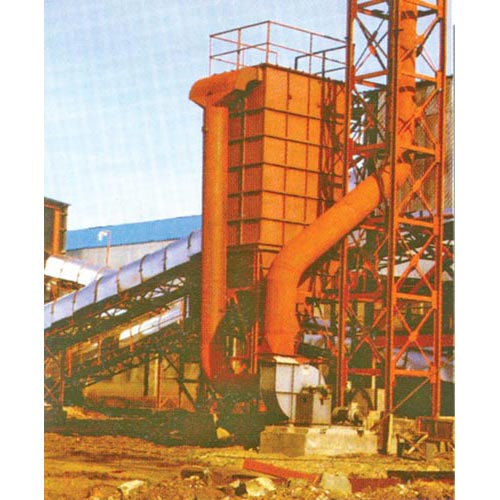

Pulse Jet Bag Filter (On/Off Line)

Pulse Jet Bag Filter (On/Off Line)

Soil & Enviro Industries offers Pulse Jet Bag Filter (On/Off Line). This is a fabric filter with fully automatic bag cleaning by compressed air pulses. It serves for the dry separation of dust from exhaust air or waste gas. These bag filters have applications in sponge iron industries, where air pollution creates havoc. There are two types of bag filters available – on line and off line – each with unique characteristics.

Principle of operation, “On-Line†cleaning system: dust-laden gas enters through the hopper/casing by suction or positive pressure. The heavier dust particles fall immediately into the hoper, while the lighter dust gets deposited on the outside of the filter bags. This dust is removed in a predetermined cycle by a pulse of high pressure compressed air. This dislodges the dust cake from the bag. The dust falls into the hopper. Bags are cleaned either by time mode or differential pressure mode. Cleaning of bags is essential to reduce operating cost and improve the performance of the bag filter. Moreover, high efficiency venturi inserts mounted on the bag opening increase the cleaning effectiveness. Bags are suspended from a tube sheet at the top of the collector and are internally supported by cylindrical wire cages to prevent them from collapsing. In an on-line bag filter, bags are cleaned row-by-row, even when the dust-laden gas is filtered. The sequence of cleaning is controlled automatically by a sequence controller. This operates the assembly of solenoid and pulse valves, which direct the air flow into the manifolds.

Principles of operation, “Off-Line†cleaning system: this version incorporates the advantages of pulsejet bag filter as well as that of reverse air bag house. Each compartment is similar to an online pulse jet bag filter. The cleaning process consists of sequentially isolating each compartment and cleaning the same with compressed air. All compartments are then cleaned automatically. Off-line cleaning is suitable for light and fine dust and for larger volumes where occurrence of fluidisation is a distinct possibility. Standard models: our many standard models have a wide range of sizes and cloth areas in rectangular arrangements to suit particular requirement of client.

The company uses 160mm dia bags with a venturi-in-cage assembly. Customising the collector through SEI options and accessories assures a collector fitted to particular needs. The company’s engineers work with the client to assess the mandatory and optional features of process to work out most efficient and optimum model. Typical application: aluminium dust, aluminium chloride, ammonium sulphate, asbestos, bagasse dust, calcium, oxide, carbon black, cement, ceramic, clay, clinker, coal, detergent, fly ash, gypsum, iron ore, kiln, lime, limestone, milk powder, saw dust, silicon carbide, soda ash, etc.

Product & Technology News

Products from Soil And Enviro Industries Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads