Schedule a Call Back

Compressed Air Filters, Clearpoint

Compressed Air Filters, Clearpoint

BEKO Compressed Air Technologies offers the new Clearpoint® Compressed Air Filters for high efficiency. With compressed-air systems working to more or less full capacity, 80% of the running costs is due to the energy consumption. The energy costs are significantly influenced by the pressure drop during compressed-air filtration. In order to maintain the required operating pressure, the compressor performance has to be stepped up to compensate for the pressure drop. The problem is higher the energy consumption, greater is the wear on the compressor and increased costs. The solution is Clearpoint with its many advantages: unique push-fit design of filter elements; large volume for longer filter element life and better filtration, and needle felt drainage layer. The threaded connections of Clearpoint compressed-air filters are generously dimensioned compared with other filters on the market. There are no energy-wasting constrictions. Housings are made of seawater-resistant aluminium and are additionally anodised. This offers increased corrosion protection, while the permanently smooth surface also reduces the flow resistance. The closing mechanism is a safety feature that allows 100% control during opening of the filter housing. If the housing is opened while still under pressure, an audible warning signal will be given. Filter elements are installed without tie-rods so that the cross-sectional area is fully available. This also reduces the flow resistance, while the space required for element replacement is only about one third compared with other designs – a great advantage under spatially restricted conditions. The unique flow-optimised compressed-air inlet into the filter element reduces the flow resistance by 75% compared with rectangular inlets as used in other filter products. To ensure optimum filtration, the condensate drain plays an important role. Filter and drain must function reliably as one unit, otherwise the separated condensate will be entrained by the compressed air. Clearpoint compressed-air filters are provided with an electronically level-controlled Bekomat 20 FM condensate drain as a standard.

Advantages:

- Integrated monitoring of the useful life of the filter to enable automatic determination of the right time for replacing the filter element

- Easily readable, informative display potential-free contact for relaying a fault signal to a control centre

- Condensate discharge at the rear through elbow connector, ideal for installation close to a wall.

Product & Technology News

Products from BEKO Compressed Air Technologies Private Limited

Catalyst for Compressed Air Treatment

Compressed Air Dryer, Drypoint RA

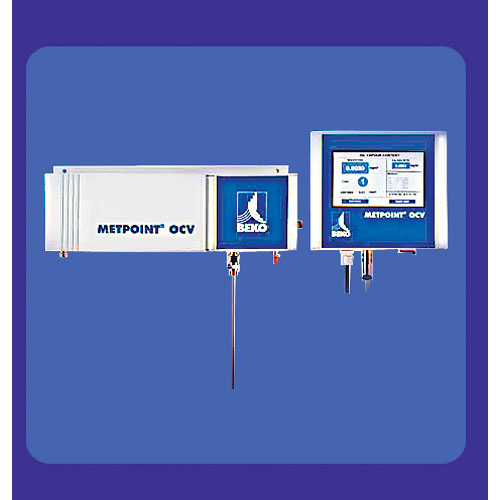

Oil Monitor For Compressed Air, Metpoint OCV

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads