Schedule a Call Back

Vapour Degreasing System

Vapour Degreasing System

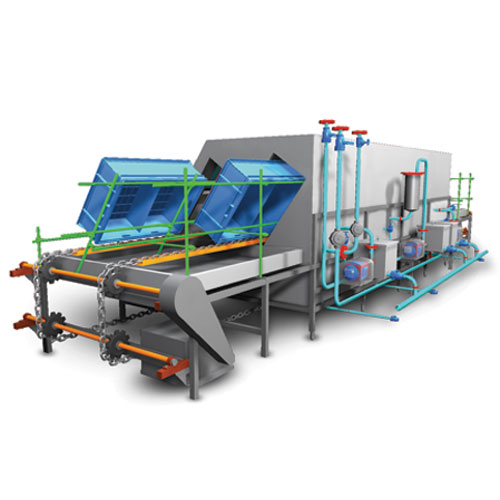

SS Engineers & Consultants offers a Vapour Degreasing System. Vapour degreasing is a surface finishing process. It involves solvents in vapour form to cleanse the work piece in preparation for further operations. The acting principle behind the vapour degreaser process is that the solvents will dissolve the contaminants on the work piece and remove them by dripping off the part. A basin of solvent is set up with a heating coil to bring the solvent to boil. As the solvent evaporates it rises to the fill-line in the chamber, above which is the much lighter air. This contains the vapourised solvent in a closed space where the work piece is placed. The solvent condenses on the more frigid work piece and the now liquid solvent dissolves the greases on the part. Some systems are designed to capture and reclaim this solvent, making the process much more economical. Benefits: can be used on electronic parts to remove excess oil, grease, wax and other non-water soluble particles because water is not used; used where water-based system are impractical; cleans and prepares part surfaces for various finishing processes like painting, welding, soldering, and bonding; issues of part oxidation and water spots are not present; and unlike vacuum degreasers, there is no solvent emitted. However they have a high cost and low production rate.

Product & Technology News

Products from SS Engineers & Consultants

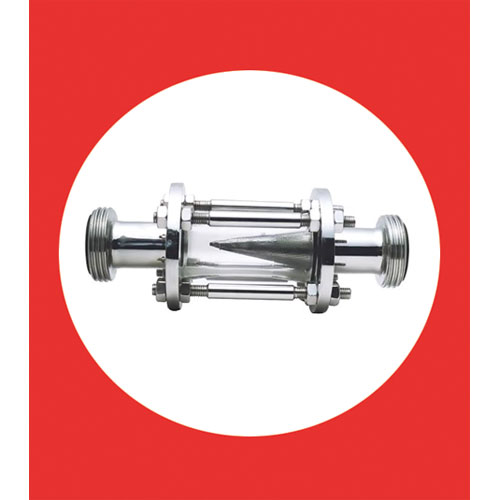

Stainless Steel Filters (Sight Glass)

Washing Machine for Cylinder Halves

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads