Schedule a Call Back

Centrifugal Pump, Massecuite Pump and Progressive Cavity Pump

Centrifugal Pump, Massecuite Pump and Progressive Cavity Pump

Indo Pump manufactures various pumps such as Centrifugal Pump, Massecuite Pump, Progressive Cavity Pump and Dosing Pump.

Centrifugal Pump:

A centrifugal pump works on the principle of conversion of the kinetic energy of a flowing fluid (velocity pressure) into static pressure. This action is described by Bernoullis principle. The rotation of the pump impeller accelerates the fluid as it passes from the impeller eye (centre) and outward through the impeller vanes to the periphery. As the fluid exits the impeller, a proportion of the fluid momentum is then converted to (static) pressure. Typically the volute shape of the pump casing , or the diffuser vanes assist in the energy conversion. The energy conversion results in an increased pressure on the downstream side of the pump, causing flow.

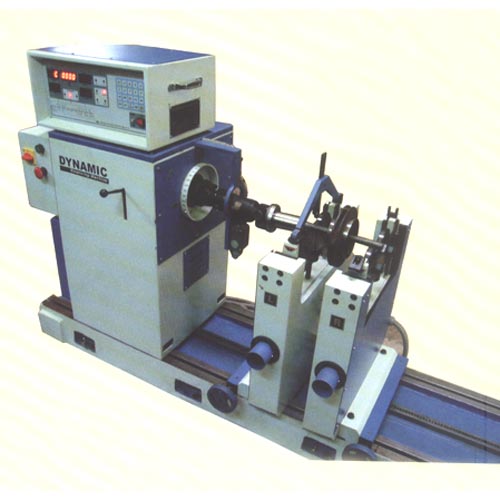

Massecuite Pump:

Indo Pump Brand Massecuite Pump is a positive displacement pump, designed principally to handle high viscosity abrasive sugar products that contain sugar crystals such as Massecuite, Magma and Molasses. Rotary pump employs elliptical rotor rotating at a very slow speed in a circular casing. It is excellent for handling Magma/ Massecuite in the sugar and other highly viscous liquids like black liquor in the paper industries. The design ensures that the sugar crystals contained within the liquids are not damaged by the pumping action, and that the pump is subjected to minimum wear. Massecuite pumps are available in various sizes. The pump size indicates the discharge flange bore in inches.

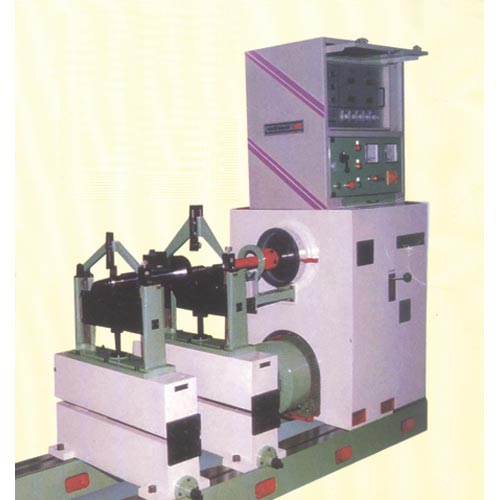

Progressive Cavity Pump:

The pumping elements in the Progressive Cavity Pumps comrise of precision machined single external helix metallic rotors and a double internal helix elastomer stators. Due to special profile of Rotor and Stator, a sealing line is formed along the axis of the rotor, which is maintained at static or dynamic condition. As the rotor turns within the stator, these cavities progress from suction to discharge end of the pump carrying the fluid. The opposing cavities fill and empty simultaneously, resulting in a pulsation less flow. The fluid travels axially with relatively low velocity and minimal agitation. The stator is made of a resilient elastomeric material and bonded to the stator tube. The important feature of the pumping principle is the ability to handle slurries and solid particles. The elastomeric stator also permits passage of solid particles due to elastomeric deformation. Progressing cavity pumps are used to handle gaseous and low viscosity liquids. The pressure capabilities of the pump are a function of the number of cavities. Indo pump progressing cavity pumps are available in a wide variety of materials-cast iron or stainless steel wetted parts and with standard elastomer materials.

Product & Technology News

Centrifugal Pump:

- Pharmaceutical and biotech: water for injection (WFI), RD, DI, process water

- Dairy: concentrated milk, cream, buttermilk, ice cream mix, milk, whey up to 50% concentration

- Food: soups, broth, flavorings, syrup, vinegar

- Beverages: high fructose corn syrup, single strength fruit juices, fruit concentrates, beer, water, liquors

- CIP: solutions, caustics, enzyme cleaners

- Personal care: mouthwash, cologne, after shave

- Oils: cooking, frying, salad

- Candy: sugar solutions, chocolate, corn syrup

- Cosmetics: shampoo, lotions

Massecuite Pump:

- Magma & Massecuite (Sugar Industry)

- For handling very high viscosity fluid

Progressive Cavity Pump:

- Molasses transfer pumps

- Press mud transfer pumps

- Sulphited syrup transfer pumps

- Raw juice/ beet juice transfer

- Melt pump

- Flocculants, chemicals

- Magma

- Massecuite

- Thick solution transfer

- These pumps are also used in Food Processing Industries, Paper Industries, Cement sheet Industries, Solvents & Refineries, Chemical Plants, Pharmaceutical Industries, Fertilizer Industries and many other industries where viscous fluid can be easily transferred by Indo Pump make Progressice Cavity Pump

Centrifugal Pump:

- Capacity: 1 to 100 cubic meter/hr

- Head: up to 65 meter

- Materials: wide choice of material like, CI, Cast Steel, SS-304/316

Massecuite Pump:

- Capacity: 15 to 60 Ton/hr

- Head: 30 Meter

Progressive Cavity Pump:

- Capacity: 20 to 100 Ton/Hr

- Head: 30 to 60 mwc

Massecuite Pump:

- Massecuite `zero' leakage

- Power saver, energy efficient

- Gentle pumping action does not damage sugar crystals

- Handles, A,B,C Massecuite & magma

- Special mechanical seal design

- High pumping capacity

- Minimum maintenance

- Easy for assembly & dismantling

- Dynamically balanced rotor & shaft

- Large suction port

- The Pumps are designed for either right or left hand assembly

- The Pump rotors are fitted with renewable bronze tips

Products from Indo Pump

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads