Schedule a Call Back

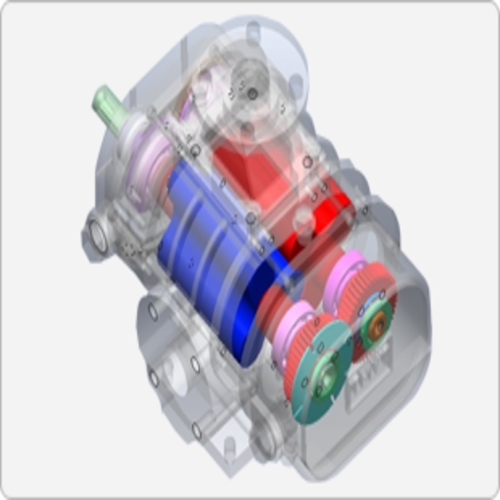

Twin Lobe Roots Blower

Twin Lobe Roots Blower

TMVT Industries Pvt Ltd manufacture a vast range of Twin Lobe Roots Blower.

Product & Technology News

- Blower:The Main Body, Side Covers are manufactured from Graded Cast Iron as per CI IS 210 FG 260. Castings are procured from Foundries of repute like Bhagwati Spherocast, Ductile Iron Foundry, etc. etc.

- Rotors : The Rotors are of S. G. Iron as per grade 400 / 015 of smaller capacities up to 1500 M3/ Hr. For larger capacities of Twin Lobe Compressors, Rotors are having Lobes in Graded Cast Iron IS 210 FG 260 Construction. All types of Rotors are with EN-8 Shafts.

- For corrosive gases we supply blower in C.I. construction with electro less nickel plating on contact parts or complete blower in stainless steel construction.

- Machining : All components are machined to very accurate dimensions with extremely tight tolerance with guaranteed interchangeability. The Castings of Casing and Main Covers (Bearing Housing) are stress relieved after pre- machining for dimensional stability at elevated temperature.

- Lobe Profiles : The Lobes of Rotors are having involute profile ensuring Uniform clearances between rotor to rotor in any position of two rotors. The profile also ensures uniform clearances between Casing and Lobes unlike providing PTFE strips which is usually done as a cheap method of manufacturing for maintaining clearances.

- The Rotor profiles are machined on CNC machines and imported Copy Shaping/Planning Equipment ensuring profile with high accuracy/finish which result in power saving.

- MTLK type blower main chamber is sealed by labyrinth seal. Four numbers piston rings are fitted on each side of rotor.

- Lubrication : Both side of side casings are oil filled. All bearings and gears are splash lubricated. This increases life of bearings and gears.

- Timing Gears : The Timing Gears are wide for more load bearing, and having helical teeth, hardened and ground, maintaining backlash within the limit of 0.03 to 0.06 mm to ensure low noise level. Same are either Press-fit on rotor shafts by Tensioning Element or having taper locking on rotor shaft by hydraulic system making mounting and dismounting of Gears much easier.

- Bearings : In case of Air Cooled Compressors model MTLK, Bearings on the drive shafts have Spherical Taper Roller Bearings to take axial as well as thrust load whereas the gear Shafts have Angular contact Ball Bearings. In case of Water Cooled Compressors Model MP, all bearings are cylindrical Roller Bearings.

- Cooling : .Air Cooled as well as Water cooled models are available for specific requirements .In case of air cooling, housing surface is cooled by convection cooling. Making fins on the housing surface increases convection. In case of Water Cooling, water is flown in the casing constantly at the specific rate which cools the blower, lobes and oil..

- Testing : All the Blower are individually tested with Test Procedure based on IS-10431/IS-5456-Rev. (BANGALORES-726/BS-1571-Part-II-Rev) for capacity, power consumption, temperature rise noise level as well as vibration level.

- MTLK Models : They are suitable for vertical as well as horizontal flow. In case of vertical flow compact assembly requiring no additional internal piping is being given.

- MP Models : In this design, for gas duty, there is special arrangement of shaft sealing. In this arrangement FOUR OIL SEALS are provided on Lobe shaft to ensure no leakage of gas to oil chamber. For additional reinforcement to this arrangement, Oil Seal, ‘O’ Ring and after space ring are provided on main shaft. This type of shaft sealing arrangement arrest gas leakage to great extent.

- LDB Models : They are used for low pressure duty in which gears are cooled by oil on one side and on the other side, bearings are cooled by grease.

- ETP Models : They are suitable for pressure upto 5000 mm WG. They are good for Water Treatment Plants. They can also used for other duties using Non Return Valves.

- Blower Unit: The Twin Lobe Compressors as well as various accessories like Two Silencers (for Suction and Discharge), Suction Filters, Safety Valves, Non Return Valves, Anti Vibration Pads, Flexible Bellows, etc. are having robust construction being as per conservative SWISS design. This ensures extremely reliable/trouble free operation and long life for critical process industries like Cement where low speed machines are usually preferred.

- Accoustic Hood :A drastic reduction of the noise level to 10 to 12 db(A) at 1 M distance is possible by employing a sound insulating hood, which can be opened to allow inspection. This hood can also be retrofitted without modifying the insulation

- TMVT make Twin Lobe Compressors (MTLK / MP / ETP Series) are enjoying tremendous reputation in the market since about 3 decades.

- Complete range of 18 Models of MTLK type covers requirements of various industries of divers nature.

- Suitable for different pressure up to 1 Kg/cm2 in Single Stage and up to 2.2 Kg/cm2 in Double Stage. Also suitable for Gas Duty as well as Vacuum Duty (Up to 600 mbar).

Products from TMVT Industries Private Limited

Verified

Verified

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Verified

Verified

Versatile Machining Capability Through Ram Type Milling & Grinding Heads

Deburring, Drilling, Boring, Tapping and Threading Machines

Verified

Verified