Schedule a Call Back

Induction Bar End Heater

Induction Bar End Heater

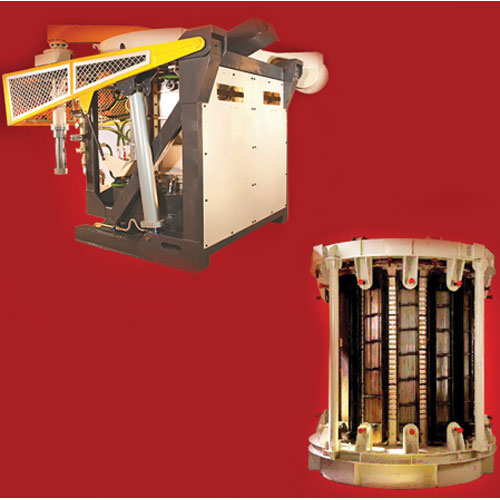

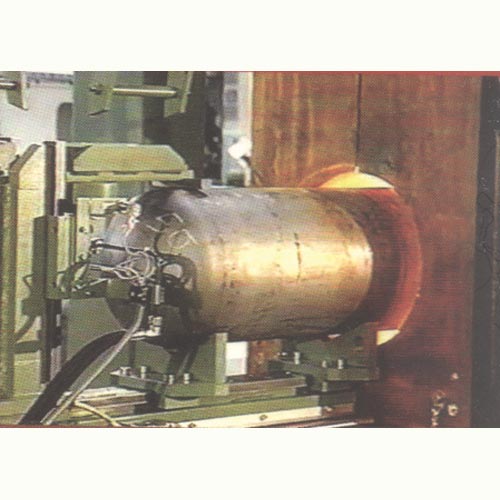

Megatherm Electronics Pvt Ltd manufactures an Induction Bar End Heater based on the latest technology. The continuous induction bar end heater is a package of static power supply, modular handling mechanism and peripherals, designed specifically for heating of only selective portions of a round or square bar. These induction heaters are suitably configured to through-heat the bar ends to the required forging temperature. The production rate, bar dia and heating count determine the power and frequency rating of the static frequency converter. The coil is also devised accordingly. The bar end heaters are offered in the following designs. As per this design the bar is placed onto the indexing conveyor at a certain point while the heated end is kept suspended. These hanging ends are heated by the induction toll (pigeon hole type) in a to and fro movement. Salient features of design: heated bars are conveniently detrained at a singular point; the design is suited to incorporate non-contact infra-red pyrometer and accept-reject mechanism. This mechanism requires the bars to be hauled manually or automatically onto fixed V-guides. As the name suggests, the bars are then hustled forward by the pneumatic cylinders through the multi pigeon-hole induction coil. This operation follows a sequence as per set cycle time. Once the cycle is completed, the pneumatic cylinders shove the bars out of the induction coil only to be followed by fresh loading. The inclined bar end heater are meant for those heated lengths which are very high compared to the total length of a bar. These heaters come with the feature of sequential heating in multi pigeon-hole coil driven through a PLC equipped operator console. The mechanism of C-channel coil offers uninterrupted movement of the bars in regular sequence, without rotation for end heating. This device works best for smaller bars with high rate of production. Here, the roller conveyor fitted with AC geared motor with drive carry the unheated length of bars. The bars once heated are dislodged from a particular point to facilitate hot handling and temperature monitoring.

Products from Megatherm Electronics Private Limited

Induction Melting & Holding Furnaces

Induction Wire / Wire Rope / TMT Bar Heater

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads