Schedule a Call Back

DRYPOINT RA Refrigeration Dryers

DRYPOINT RA Refrigeration Dryers

It is not the investment costs that determine the cost efficiency calculation regarding refrigeration dryers – but the operating costs. Considering an operating period of five years, only between 20 and 30 per cent of the total costs are allotted to the pure investment, while 70 to 80 per cent are allotted to the ongoing operating costs. These costs are split equally between electricity costs, flow resistances in the system and compressed air losses through leaks. Pressure drop at critical spots must be compensated by enhanced compressor performance and the resulting additional energy demand.

With DRYPOINT RA, these operating costs can be reduced by almost half, considering a period of time of five years. In the return-on-investment calculation, the full potential of the new refrigeration-dryer generation is proven: the dryers pay off within an operation time of only six months.

The air-cooled DRYPOINT RA compressed air refrigeration dryers complement the BEKO TECHNOLOGIES dryer programme with another cost effective alternative. The comprehensive RA model range of products allows optimum adaptation of the

compressed air processing to individual operating conditions. All models excel in minimum pressure loss even with varying work loads and in their low energy consumption. The standard series comprises refrigeration dryers with performances from 20 to 8800 m³/h.

Products from BEKO Compressed Air Technologies Private Limited

Catalyst for Compressed Air Treatment

Compressed Air Dryer, Drypoint RA

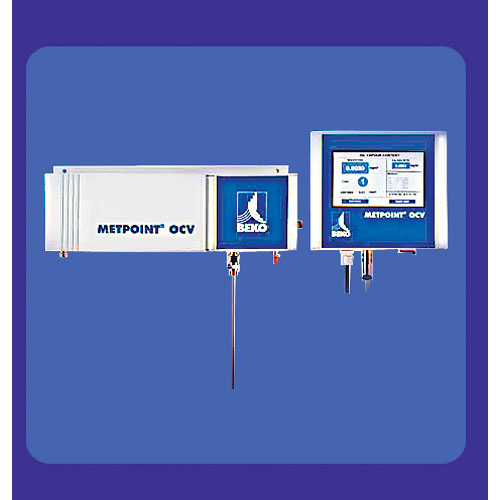

Oil Monitor For Compressed Air, Metpoint OCV

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads