Schedule a Call Back

Cast In Aluminium And Bronze Heaters

Cast In Aluminium And Bronze Heaters

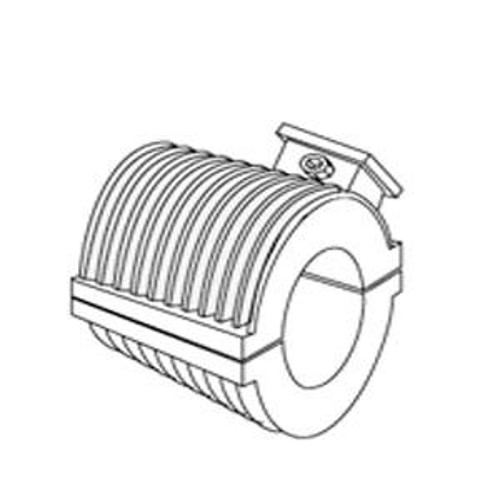

Omega Heater Industries offers Cast In Aluminium And Bronze Heaters. Omega Cast-In heaters combine top quality tubular heaters and high thermal conductivity non-ferrous alloys. The heater elements are tested on a 100% basis before and after casting. Modern foundry techniques ensure a dense, porosity free casting. After casting the heaters are machined to ensure a close contact on the working surface. Cast In heaters can be supplied with clamping straps or with built in clamping means. Omega can supply heaters with leads in armor, post terminals, terminal housing and a variety of electrical terminations. Standard cooling tube terminations are also available. Casting quality is maintained by periodic radiographic testing. Diagnostic radiography services are available if required. Omega quality construction in a roller heater design developed especially for the Hot Stamp Industry.

Efficient and long life ceramic heaters provided in standard and custom designs. Omega roller heaters feature the quality design practices associated with our ceramic heater bands combined with the innovative design requirements for the heating of rotating rollers. Omega roller heaters freature a 63% open perforated metal liner, which assures maxium heating surface exposure while providing the proper support to maintain a positive clearance between the ceramic heating surface and the roller. The addition of a "Black Star" coating provides the optimum design for radiant and convective heat transfer.

- TEMPERATURE -Up to 1200F

- WATT DENSITY-Up to 35 watts/square inch

- VOLTAGE - Up to 480 volts - Single and three phase

- ROLLER SIZES - 2" diameter and up. 1-1/2 width and up (in 1/2" increments)

- TERMINAL - 1/4-20 Post terminals standard

- SHEATH - Stainless Steel

- MOUNTING COLLARS - 1/4, 3/8, 1/2, 5/8, 3/4Designed Specially for Hot Stamping Efficient

Products from Omega Heater Industries

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads