Schedule a Call Back

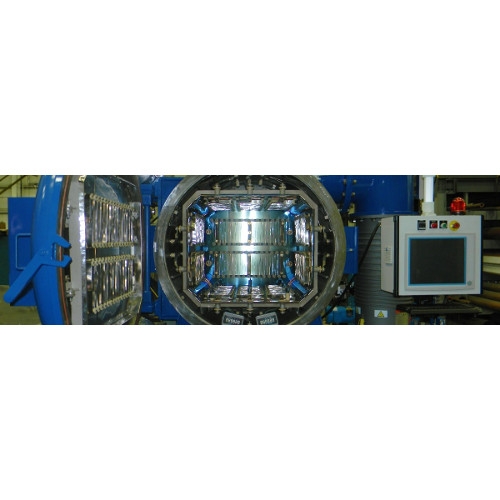

Vacuum Aluminum Brazing Furnaces

Vacuum Aluminum Brazing Furnaces

Inductotherm (India) Pvt Ltd offers Vacuum Aluminum Brazing Furnaces. Vacuum Aluminum Brazing (VAB) is utilized to perform fluxless brazing of Aluminum components in a high vacuum environment. The process demands tight control of temperature uniformity together with low vacuum leak rates and high repeatability. VAB will provide a component with very clean, high quality, high strength brazed joints. Whilst offering a wide range of standard vacuum aluminum brazing furnace designs for a variety of applications, Consarc also has the flexibility to design for bespoke or individual customer requirements.

Product & Technology News

- Closely spaced ribbon heating elements with the edges facing the work provide the best in uniform heating characteristics.

- Temperature uniformity +/- 5oF

- Multiple ‘trimable’ heating panels for balance of heat input to match the workload and fixture thermal characteristics.

- Trimable heating panels up the height of the hot zone allows the heat input to be trimmed to match components /charge loads of varying height.

- Aluminum debris will pass through the edge facing bottom heating element panels – minimising potential for burn outs.

- The hot zone element panel modules can be easily removed to permit cleaning of the furnace. Individual panels can also be removed without the need for a full hot zone strip down.

- Element repairs made simple. Small sections of the strip elements can be repaired without the need for full replacement

- Hot zone shields are overlapped and spaced to permit easy escape of gases from the work assembly to provide optimum vacuum performance.

- The tank walls of the furnace are maintained in a hot condition to prevent condensation of atmospheric moisture when the chamber door is open.

- Insulated non-water cooled power feedthroughs prevent condensation of magnesium which reduces arcing potential.

- Internal inert gas cooling systems or external air blast cooling stations are available

- Fully integrated and automated loading systems.

- Integration with a Vacuum Deoiing furnace to provide an “in line” process system for high productivity with minimum product handling.

- Extensive process experience.

- PLC and PC SCADA providing completely automated control of the brazing furnace and data recording

- Compliant with NADCAP and AMS2750 requirements if required

- Complete furnace system including all interconnecting services, water lines, air lines, gas lines and electrical cables.

- Fully assembled and functionally tested prior to shipment

Products from Inductotherm (India) Private Limited

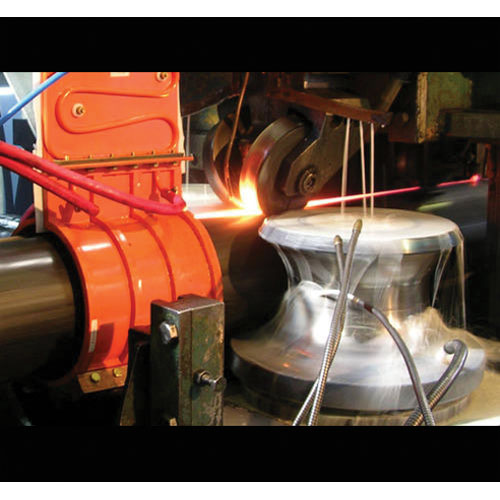

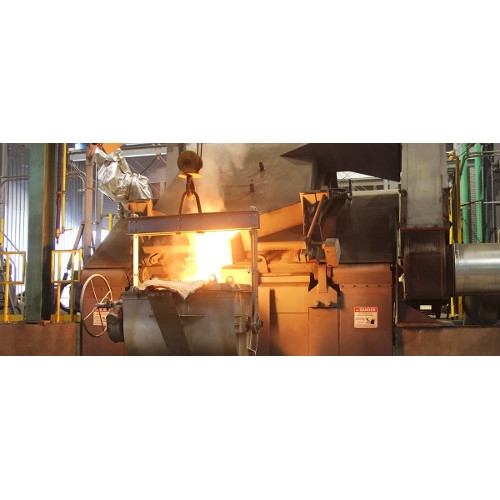

Electro Slag Remelting Furnaces

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads