Schedule a Call Back

Travelling Grate Boiler

Travelling Grate Boiler

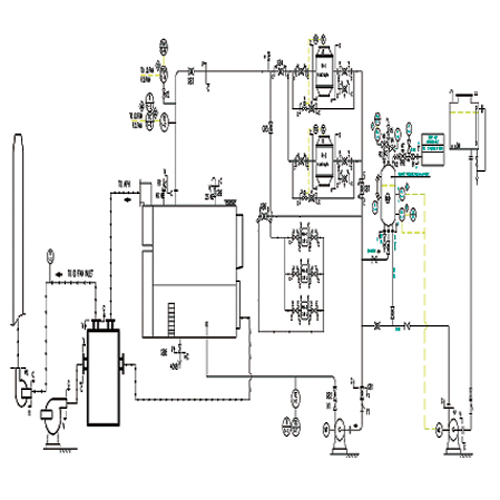

Veesons Energy Systems offers Travelling Grate Boilers. These continuous ash discharge spreader stokers are ideally suited for efficient combustion of coal, bagasse and biomass fuels. The grate travels from rear towards the front, while the fuels are thrown into the furnace from the front. The grate movement is controlled with the help of a hydraulic drive. Mechanical spreaders are used for high-density fuel like coal to spread the fuel into the grate and pneumatic spreaders are used for low density fuels like bagasse, wood chips, rice husk, soya stalk, paddy straw, bamboo chips, etc. This technique assures even and uniform fuel bed on the grate. The grate bars shall be protected from high temperature by the bed ash layer on the grate. Apart from this, combustion air coming from underneath the grate cools the grate bar and thereby keeping the metal temperature well within the limits. The air chamber below the grate is compartmentalized for regulating the airflow across the grate for further improving the combustion throughout the entire grate. Major components: grate bar, front shaft with drive sprockets and driving unit, rear shaft with idlers, chain links, supporting crossbeams with skid bars, grate bar retainer, skid ramp, return chain support, front and rear refractory seals, front seal – lower, front, side and rear frames, and bearings in the CI housing and carbon bushes. Advantages: a wide range of fuels can be fired; boiler start up is very easy; and most suitable for sugar industries since the by product bagasse can be fired in 100%.

- Alloy cast iron grate bars, with narrow width and long length

- They provide controlled air opening in the grate due to reduced number of lateral clearances

- Drilled holes in orifice shape provided in the grate bars account for major part of grate opening

- High tensile materials are used for construction of robust chains, pins and bushes are hardened for long service life

- Sprockets and idlers are in cast steel construction

- Easy replacement of grate bars – in the unlikely event of replacing a damaged grate bar, the steps involved are simple and quick

- For stoker shaft bearing system, a heavy-duty design is offered capable of handling all types of fuels to withstand the rigorous duties involved

Products from Veesons Energy Systems Private Limited

Water Cum Smoke Tube Boiler, Ecosteam-Fub

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads