Schedule a Call Back

“Outlook for Indian plastics machinery companies is brightâ€Â

Interviews

Interviews- Oct 01,18

Related Stories

Robotics promises big productivity gains in auto industry: GlobalData

In a dynamic era of technological advancement, the automotive industry stands at the precipice of a revolution driven by robotics, as per GlobalData’s new research report, “Robotics in Automotiv..

Read more

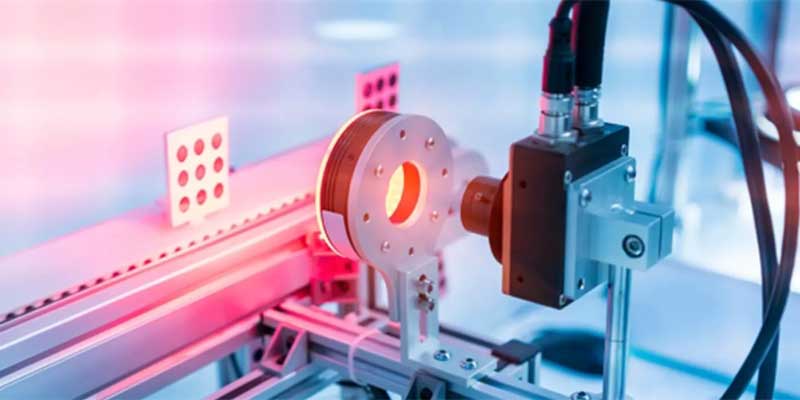

Machine vision players opt for acquisition route for growth

While many new vendors are entering the machine vision market, global corporations are investing in acquiring technology and expertise in each of the machine vision component sectors, says Jonathan ..

Read more

Rockwell's new study finds GenAI as top tech investment for manufacturers

According to Rockwell Automation’s Global State of Smart Manufacturing Report, AI ranks as the top capability that manufacturers believe will drive the biggest business outcomes. 83% of manufactur..

Read moreRelated Products

Rubber Sheets Material

Talbros Sealing Material Pvt Ltd offers a wide range of rubber sheets materi Read more

Rail Rubber Pad

Chamunda Enterprise offers a wide range of rail rubber pad.

Insulation Polyester Film

TMA International Private Limited offers a wide range of insulation polyester film.