Schedule a Call Back

BARC collaborates with Intech Additive to make 3D printed metal components

Industry News

Industry News- Aug 11,22

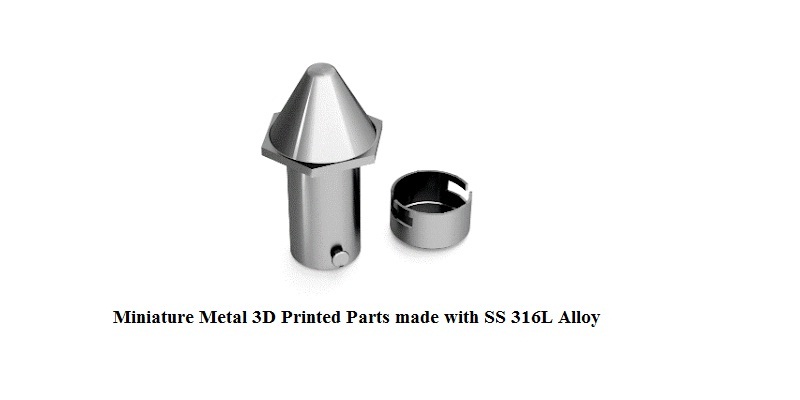

- Length - 33 mm

- Cylindrical housing OD - 11.6 mm

- Cylindrical housing ID - 10 mm

- Retainer ring thickness – 1.5 mm

Related Stories

Smart security seal to prevent utility meter tampering

Safcon Seals Pvt Ltd has developed unique smart security seal to protect utility meters from tampering to prevent the revenue loss to the utilities.

Read more

Evolving Manufacturing Trends: A Glimpse into 2024

Traditional manufacturing methods are being redefined by the rise of smart factories. By 2024, these establishments will have integrated systems, artificial intelligence (AI), and the Internet of Th..

Read more

Safcon Seals develops Snap-Lok security solution for water meters

Safcon Seals has developed security solution for water meter protection from theft. Combination of Snap-Lok water meter connection nut lock and RevGuard tamper resistant security seal is most effect..

Read moreRelated Products

Industrial Desalination System

Shakunth Aqua Products offers a wide range of industrial desalination system. Read more

Industrial Castors & Wheels

H M Gulamali offers a wide range of castors and wheels manufactured by Blickle, Germany. Read more

Foxconn, Nvidia join forces for AI factories revolutionising tech production

Taiwanese technology giant Foxconn and leading US hardware company Nvidia revealed their partnership to establish "AI factories," advanced data processing centres geared toward driving the production Read more