Schedule a Call Back

“Automotive and Defence to observe major scope for vacuum impregnationâ€Â

Interviews

Interviews- Mar 01,18

Related Stories

Igus' QuickRobot online tool helps in quick configuration of robots

Highly flexible cables and hoses ensure that robotic applications are supplied with energy, data and media. Energy supply systems are required to protect them safely even with high dynamics and tors..

Read more

Igus invites applications for Vector award

The Vector award for the best energy chain applications is entering its eighth round – and applications will be accepted until February 11, 2022.

Read more

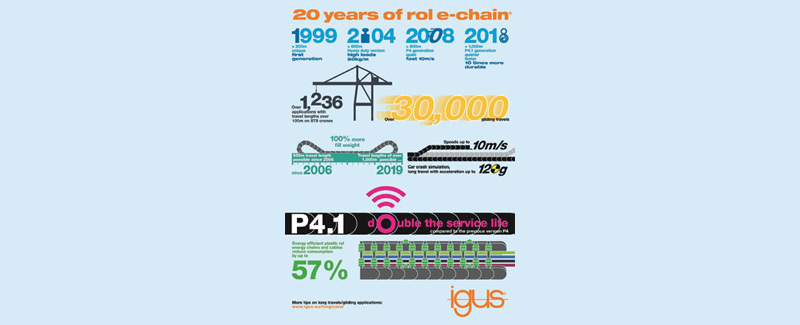

Igus roller energy chains evolved to develop energy supply systems

Igus, the motion plastics specialist, known for its roller energy chains has evolved over 45 years, is developing energy supply systems that reliably guide cables for all media - such as ethernet, s..

Read moreRelated Products

Tata Motors unveils facilities for development of Hydrogen propulsion tech

Tata Motors, India?s largest automobile company, unveiled two state-of-the-art & new-age R&D facilities for meeting its mission of offering sustainable mobility solutions. The unveilings constitute of Read more

Tata Motors plans petrol powertrain for Harrier and Safari SUVs

Tata Motors is in the process of developing a new petrol powertrain for its premium sports utility vehicles, the Harrier and Safari, as confirmed by a senior company official. Currently, these models Read more

Electric Vehicle Charger

RRT Electro is engaged in manufacturing of customized Power Electronic Products over two decades having capability to Design, Develop, Prototyping, Regulatory Compliance testing & Certification, Manuf Read more