Schedule a Call Back

HARTING helps ARBURG to provide reliable product quality data

Industry News

Industry News- Apr 11,19

Related Stories

Lubrizol opens new Global Capability Center in India at Pune

Center expands on Lubrizol’s 2023 $150 million investment commitment to support growth in India

Read more

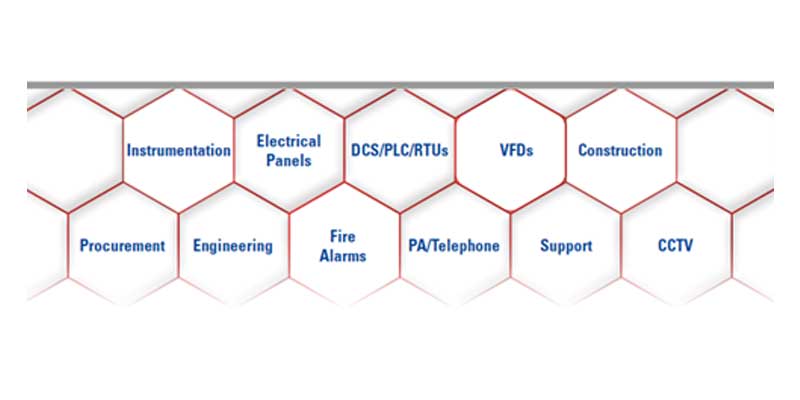

Autosys: An expert you can rely on

Autosys and its leadership team has over 30 years of experience across 500+ projects in a wide variety of sectors and industries.

Read more

Tata Chemicals joins hand with IITB-Monash for clean energy innovation

Under this agreement, Tata Chemicals commits to supporting the next-gen technology research led by the IITB-Monash Research Academy focused on the transformative potential of perovskite materials in..

Read moreRelated Products

Fluorescent Pigments for Traffic Cone

Aron Universal Limited offers a wide range of fluorescent

pigments for traffic cone.

D C Choke

Miracle Electronic Devices Pvt Ltd offers a wide range of D C choke.

Temperature Control With Solder Bath

Hallmark Electronics offers a wide range of solder bath with temperature control. Read more