Schedule a Call Back

Atlas Copco expands compressed air and nitrogen product ranges

Industry News

Industry News- Jun 23,18

Related Stories

Hengst Filtration opens filtration plant in Bengaluru

Spanning across 36,000 sq ft, the Yelahanka facility will manufacture a diverse range of products across multiple verticals, exemplifying the German firm’s long-term growth strategy for India, say..

Read more

Evolving Manufacturing Trends: A Glimpse into 2024

Traditional manufacturing methods are being redefined by the rise of smart factories. By 2024, these establishments will have integrated systems, artificial intelligence (AI), and the Internet of Th..

Read more

Industry leaders react positively to the interim budget 2024-25

The Interim Budget also contained a number of announcements and strategies indicating directions and development approach for making India Viksit Bharat by 2047. Here are the reactions from the indu..

Read moreRelated Products

Air Compressors

Hallmark Compressor Private Limited offers single stage air compressors. Read more

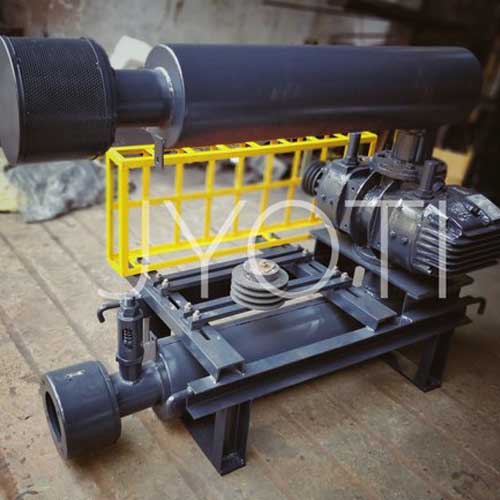

Lobe Compressor

Jyoti Air Tech Engineers offers a wide range of lobe compressor.

Read more

Compressor

Indmark engages as a retailer and exporter of a wide range of single stage compressor.