Schedule a Call Back

“Copper heat exchangers are now recapturing market shareâ€Â

Industry News

Industry News- May 01,19

Related Stories

Revolutionising HVAC efficiency with renewable energy and low-carbon materials

HVAC systems, crucial for maintaining indoor comfort, have long relied on fossil fuels, raising concerns about environmental impact and energy efficiency. Even so, a transformative moment, aptly cal..

Read more

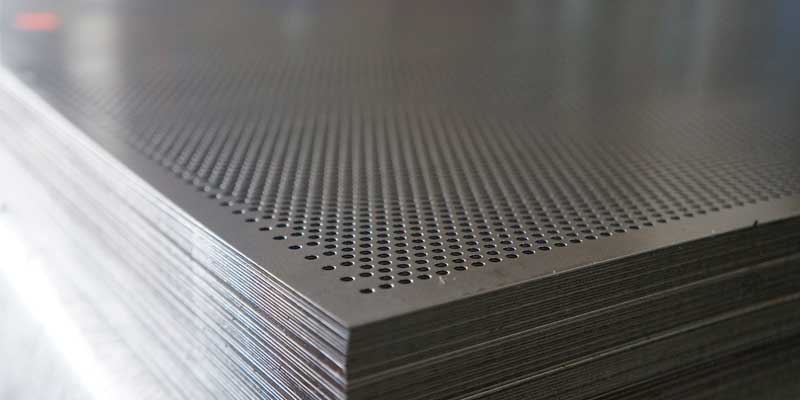

Diamond Metal Screens offers high-quality perforated sheets

Transform your projects with the ultimate blend of functionality and aesthetics using Diamond Metal Screens’ premium perforated sheet metal. Crafted with precision and engineered for excellence, t..

Read more

ACREX India 2024: Exploring future horizons in HVAC Innovation

Organised by ISHRAE and Informa Markets in India, the premier exhibition takes place from February 15 to 17 at IEML, Greater Noida, Delhi-NCR.

Read moreRelated Products

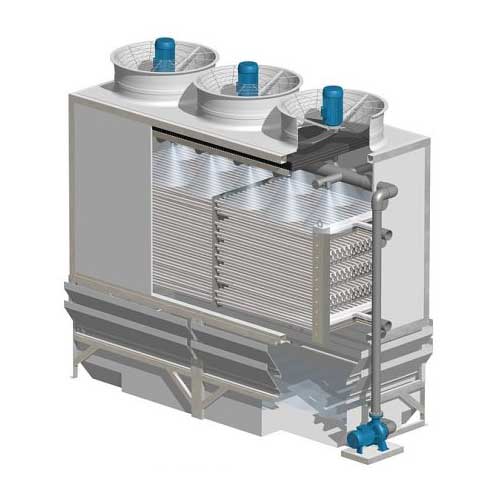

Cross Flow Cooling Tower

World Cooling Towers offers a wide range of cross flow cooling tower.

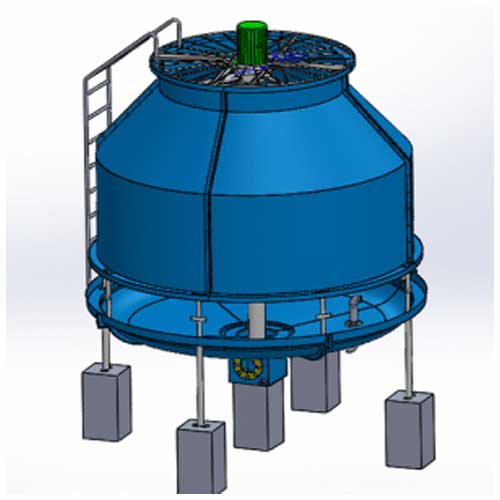

Counter Flow Cooling Tower

World Cooling Towers offers a wide range of counter flow cooling tower. Read more

Evaporative Cooling Towers

World Cooling Towers offers a wide range of evaporative

cooling towers.